Custom Motorised Cable Drum Movers: A Reel-y Safe Solution

In a remarkable display of customer-focused problem-solving, MasterMover has once again demonstrated its leadership in engineering customised material handling solutions.

In this blog, we explore the latest addition to MasterMover’s extensive portfolio of custom engineered solutions. Having recently designed and delivered two specialist cable drum handling systems for a customer in the defence industry, we’ve further cemented our reputation as a pioneer in custom engineered handling solutions.

4x Machines Shipped

500 - 3000kg Capacity

2x Custom Machines

Size, variety & safety: the challenges of cable management & handling

Subsea cables are the invisible backbone of global communications, carrying over 95% of international data traffic. They are essential for internet connectivity, and telecommunications, and are sometimes even used for power transmission between regions.

Considering the crucial role these systems play in the infrastructure of the modern world; the effective handling of cable reels is crucial for maintaining the integrity of global connectivity.

For this customer, moving large and cumbersome cable reels and drums was a challenge. They needed a safer, more efficient way to move a diverse range of cable reels and drums.

Project engineers were tasked to find a solution that could handle various drum sizes and weights while prioritising worker safety in their production environment.

Each reel, weighing between 500kg and 3,000kg, presented its own set of handling challenges.

The variation in drum materials, including both wood and metal constructions, added another layer of complexity to the task of finding a universal solution capable of safely moving the drums.

Project requirements

In this project, the customer's operations required the movement of large commercial cable reels both indoors and outdoors, including navigating a challenging slope at the entrance of the building.

This required a solution that was not only powerful but also highly manoeuvrable and capable of operating reliably beyond a smooth factory floor.

However, the most pressing driver for this solution stemmed from a previous safety incident - a finger trap accident during the cable spooling process highlighted the urgent need for a safer, more efficient system.

This incident underscored the critical importance of developing a solution that prioritised operator safety without compromising on functionality and versatility.

Considering their unique requirements, this customer needed an expert – a business with a proven pedigree in designing and manufacturing custom handling solutions, leading them to contact the team at MasterMover.

Our team of expert engineers worked with the customer to fully understand their application needs. Following a staged-gate process, engineers collaborated with the customer every step of the way to design a solution that was actually going to solve the specific challenges they were facing.

Motorised cable drum movers deliver on safety

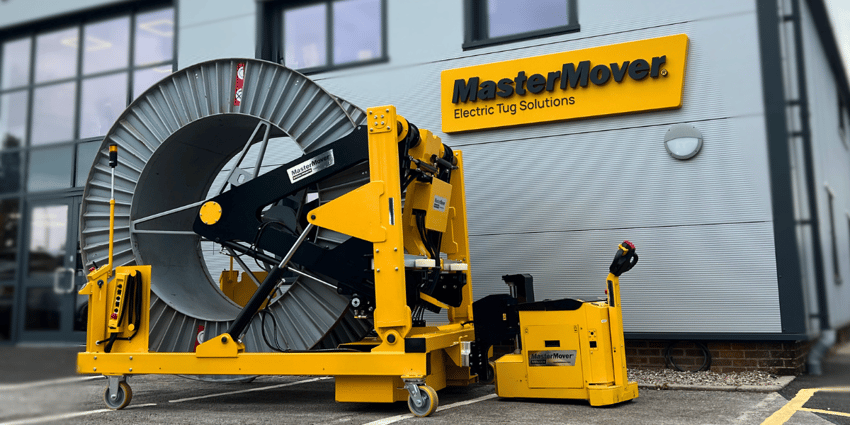

Following a detailed consultancy and design process, MasterMover engineers created two custom cable drum handling systems designed to work alongside our electric tugs.

Independently powered by batteries, the cable reel movers can also be utilised on their own, or combined with electric tugs to transport cable drums across the customer’s facility.

Working closely with the customer, this custom engineered cable mover delivered on each of the unique requirements:

Uncompromising Safety

At the heart of the new system is a design that eliminates the risk of finger trap incidents by fully mechanising the spooling process and allowing operators to stand clear.

This focus on operator safety ensures that the customer can carry out their critical work without the risk of injury.

Versatile Handling Capabilities

Recognising the diverse nature of the customer’s cable reels, MasterMover engineered a system capable of managing various drum diameters, types and materials – with a maximum capacity of 3,000kg.

Working alongside our MasterTug electric tugs, the reel movers enable this customer to achieve flexible handling across the facility.

This versatility ensures that the solution can adapt to the customer’s evolving needs and different cable specifications – whether that be the material, size or weight of drum.

Cable Spooling Feature

Perhaps the most innovative aspect of this custom cable reel mover is its unique ability to not only move reels safely but also facilitate the spooling of cables.

The system offers excellent versatility in cable movement by allowing operators to spool cables both on and off the reels. This feature greatly enhances operational efficiency and flexibility.

Key features of the system

- A single-design enables the movement of all reel sizes for this customer

- Hydraulically-powered clamp enables reels to be clamped and lifted

- Motorised spool and unspooling of cables via a hydraulic motor

- Dedicated high-capacity battery pack to keep operations moving

- Braked spool motor ensures controlled cable management

Experience in custom engineering

This project is a testament to MasterMover's position as a leader in custom engineering. Our commitment to innovation and excellence has not gone unnoticed in the industry...

We’ve been recognised by prestigious accolades such as the King's Award for Enterprise in Innovation and The Manufacturer MX Award for Product Design & Innovation.

The custom-designed cable drum handling system demonstrates our ability to innovate beyond our core electric tug solutions.

It showcases our engineering expertise in creating comprehensive material handling solutions that address complex challenges across various industries, from manufacturing to defence and beyond.

For this customer, the ability to safely move and spool cables with a single system led to significant improvements in operational efficiency, reduced workplace accidents, and increased productivity.

As industries continue to grapple with the challenges of handling increasingly complex loads and systems, MasterMover is poised to deliver fully customised solutions that help shape the future of safe and efficient material handling.