Continue reading

Continue reading

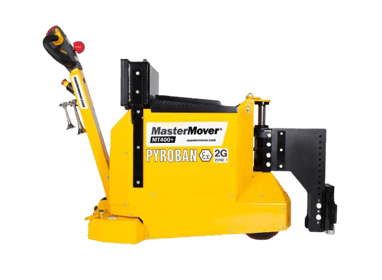

Oil & Gas Manual Handling Equipment

Thank you for submitting your demo request.

A member of the team will be in touch shortly.

Thank you for submitting your consultation request.

A member of the team will be in touch shortly.

Typical electric tug applications

For offshore and onshore operations, our electric tugs assure the safe and controlled movement of heavy loads. Whether it’s in a petrochemical plant or an oilfield, leading businesses trust our electric tugs to work in some of the toughest environments.

- Subsea trees

- ROVs

- Pipes & pumps

- Machines sub-assemblies

- Valves and wellhead equipment

- Umbilical cables

Electric tug benefits for the oil & gas industry

Suited to hazardous environments

Our specialist range of electric tugs meet ATEX/IECEx standards, ensuring a safe operation in potentially explosive environments.

Built tough

Offshore operations present challenging conditions for MHE. Our tugs are built to perform in the toughest conditions, whether that’s working outside or on metal grating.

Unlock greater flexibility

Ideal for bridging the gap between fixed infrastructure like overhead cranes, electric tugs deliver improved flexibility.

Custom engineering

Complex handling challenges need innovative solutions. We can provide tailored solutions engineered around your specific requirements.

Popular electric tugs for the oil & gas industry

Our electric tugs in petrochemical settings

Things to consider for petrochemical settings

- Weight capacity – Equipment in the oil and gas industry can be particularly heavy so it’s important to work with suppliers with proven expertise in heavy load movement.

- Environmental requirements – Ensure your chosen supplier has experience in providing ATEX rated equipment.

- Flooring – Offshore chequer plating and grating can impact the performance of handling equipment. Choose a supplier with a machine designed to work in these conditions.

- Durable materials– Will the machines going to be used offshore? If so, consider whether stainless steel is required to prevent corrosion.

Case study

43 Electric tugs streamline offshore maintenance at the Tengiz oilfield

Explore how 43 custom-designed electric tug solutions are supporting maintenance processes at an offshore oilfield in Kazakhstan. Following a rigorous conversion process, these machines are ATEX rated and designed to handle challenging offshore conditions.

Trusted by industry leaders

Electric tugs are used by global petrochemical giants to deliver the safe, controlled movement of heavy loads in the most challenging environments.

MasterMover are easy to work with and all products performed as advertised. Moved our heavy products with ease!

Parker MacciantiMechanical Engineer

Why choose MasterMover?

- The world's leading manufacturer of electric tugs for over 25 years

- Over 40+ electric tugs to choose from

- Unrivalled range of technology and control options available

- Proven experience in the oil and gas industry

- In-house custom engineering capabilities

- Winner of the King's Award for Innovation 2023 & Queen's Award for International Trade 2021

- Global sales and support

We're here to help

If you’re looking to improve safety, remove the risk of injury and unlock greater operational efficiency, we’re here to help. Speak to our team to discuss your application.

Your Questions, Answered - FAQs

Yes, all of our electric tugs can be converted to meet ATEX standards. Our electric tugs can be converted to operate in zones 1 and 2 (gaseous explosive environments) and zones 21 and 22 (powder or dust explosive environments) to meet ATEX and IECEx standards.

Working with best-in-class explosion-proofing providers, MasterMover ATEX electric tow tugs can safely work in hazardous environments, allowing you to maximise workplace safety and efficiency.

Electric tugs are battery powered, with interchangeable batteries or lithium options available, electric tugs can deliver 24/7 operation to keep your processes moving.

Offering zero emissions from the point of use, electric tugs are ideally suited for indoor use, replacing internal combustion engine (ICE) powered equipment such as forklifts or tow tractors.

A range of coupling options are available across the range that maximise performance, security and safety.

Custom coupling solutions can also be designed for unique applications.

Interested in learning more? Read the latest articles

Continue reading

Continue reading

ATEX Electric Tugs Provide Safety and Efficiency North Sea