Material Handling Equipment (MHE) Guide

Material handling is an essential part of almost all production environments, and different types of material handling equipment are relied on to support processes and tasks throughout the supply chain.

Stay tuned for all the latest industry insights and news.

What is Material Handling Equipment?

Material handling equipment (MHE) covers a range of machines and systems used to move materials from one place to another or facilitate safe storage.

It includes equipment for storing, transporting, and managing materials and products throughout production processes.

4 Key Types of Material Handling and Lifting Equipment

1. Storage & Handling Equipment

The simplest type of material handling equipment is often that which is used in the storage of materials and equipment.

Storage equipment includes mezzanines, storage racks, bins, shelving and stacking frames. Storage and handling equipment ensure materials remain organised and safely stored.

2. Bulk Material Handling Equipment

Bulk material handling equipment is specifically designed to transport loose bulk materials and is often used to move materials within food and chemical production.

This covers handling equipment including hoppers, reclaimers and conveyor belt systems.

3. Industrial Trucks

The term industrial truck covers an extensive range of material handling systems, from small, manually operated tools to large, motorised vehicles.

Some of the main types of industrial trucks are:

Forklifts

A forklift truck is the most recognisable industrial lift truck for most people. This industrial truck features forks at the front that can be raised or lowered to lift loads such as pallets or crates.

Forklifts are used in many industries to transport goods and materials and are available as battery-powered units or as diesel powered, using an internal combustion engine design. Diesel forklifts are often used in industries like heavy plant manufacturing, where loads are particularly heavy.

Towing tractors

Towing tractors are vehicles designed for towing wheeled loads such as carts or dollies. Typically, they feature steering controls and pin coupling and are used to tow loads weighing up to 6,000kg in factories and warehouses – though higher towing capacity machines exist. Towing tractors are common place in industries such as automotive, logistics and manufacturing.

Hand truck

A hand truck, or sack truck, is a simple, L-shaped device used to move loads by hand.

Pallet truck

Also known as a pallet jacks, pump trucks or pallet trucks are designed to lift and move pallets.

They are available as either manual pallet trucks or electric pallet trucks.

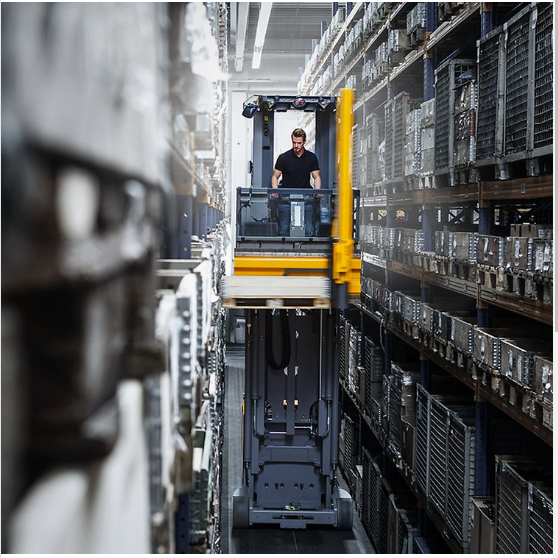

VNA truck

Very narrow aisle trucks (sometimes known as turret trucks) are designed to lift pallets in tight warehouse environments.

Electric tow tugs

Also known as electric tugs and electric tows, are battery-powered machines specifically designed to move heavy-wheeled loads within industrial environments.

Electric tow tugs are a crucial type of material handling equipment relied on by businesses to reduce manual handling or as a safer alternative to forklifts.

Cranes

Cranes are heavy-duty solutions that lift large and heavy materials, typically within factory environments. They’re predominantly designed for tasks that involve lifting materials to different heights and positions.

4. Engineered Systems & Advanced Material Handling

Engineered and automated handling systems are typically more complex than other material handling equipment and can often include multiple pieces of equipment.

Here are some of the most common types of engineered material handling systems:

Automated guided vehicles (AGVs)

Autonomous load-moving systems designed to mobilise loads throughout processes while interacting with the environment.

Automated storage and retrieval systems (AS/RS)

An Automated Storage and Retrieval System typically utilises robotics to automate warehouse operations, including picking and processing to interact with storage racks and existing storage equipment.

Robotic delivery systems

Which automate tasks such as pickup and delivery using robots programmed with specific instructions

Automated conveyor systems

Move components swiftly between various processing points

Other Types of Material Handling Equipment

Alongside the four key types of material handling, other types of equipment are available such as overhead cranes, hoists, skate systems, lift tables and many more.

Which Type of Material Handling Equipment do I need?

Each environment and application is distinct, and as a result, there is a wide range of material handling equipment available. The specific processes, environment, and application you have will determine the most suitable type of material handling equipment for your needs.

If you want to lift heavy, palletised components weighing over 6,000kg onto shelving, a forklift may be a better solution than a pallet truck. While an electric pallet truck may be a better option to move 500kg pallets in a small warehouse.

Materials Handling Equipment for Specific Operations & Industries

Material handling and lifting equipment is typically designed around a specific operation. So, while forklifts and pallet trucks are designed to lift pallets, you wouldn’t use them to move wheeled loads. In this instance, an electric tug, a machine specifically designed for this application, would be the correct option.

Each type of material handling equipment is suited to specific applications and selecting the correct tool for the job is crucial.

Whether you’re looking for storage equipment, material lifts, manual handling equipment or advanced engineered systems to transport loads, the market boasts an expansive range of material handling solutions.

The ultimate guide to material handling

Material handling equipment

Looking to understand material handling in a little more detail?

We’ve compiled some helpful resources to get you started.

-

10 Principles of MHE

-

Advanced MHE

-

Best forklift trucks

-

Material handling in manufacturing

-

Forklift trucks vs electric tugs

-

Shunters vs electric tugs

-

Tow tractors vs electric tugs

-

Overhead cranes vs electric tugs

-

AGVs vs Traditional MHE

-

A fork-free future

-

What is intralogistics?

-

Diesel forklift alternatives

-

Benefits of tugger trains

Considering the 10 Principles of Material Handling

Material handling systems should support processes to improve efficiency, productivity, safety, and profitability, while reducing costs and waste.

To achieve this, there are ten principles of material handling that everyone involved in the process should follow, whether reviewing existing methods or looking at new processes.

-

Planning

Identifying what needs to be moved and how.

-

Standardisation

Understanding how or if processes can be standardised.

-

Work

This involves minimising human effort and physical involvement.

-

Ergonomics

Assessing tasks to minimise physical strain and fatigue.

-

Unit Load

Can materials or loads be consolidated into a single load?

-

Space Utilisation

Maximising the use of available space for handling and storage.

-

System

Are systems coordinated? Can they be improved?

-

Environment

What is the impact of material handling processes on the environment?

-

Automation

Can technology be used to automate processes?

-

Life Cycle Cost

Involves understanding the entire cost of material handling processes, including initial investment, spare parts and maintenance, staff costs and uptime.

Introducing Tugger Trains

Tugger trains, commonly known as tugger carts, represent a modern approach to efficiently manage materials in industrial settings like factories and warehouses. Essentially, they employ a motorised vehicle like an electric tug (referred to as the tugger) or a tow tractor to pull a set of carts or trailers equipped with castors, each of them carrying materials, components, or products.

Transporting Heavy Loads on Wheels with Ease

Need a material handling solution to move heavy-wheeled loads?

Electric tugs keep wheeled loads safely on the ground, deliver unrivalled control, and are license-free – meaning you can easily integrate them into existing processes and tasks, driving operational efficiency and improving safety.

Electric tugs could be the solution for you if you are…

- Searching for materials handling equipment to move wheeled loads

- Looking to reduce reliance on forklift trucks

- Improve control and precision when moving heavy items

- Remove manual handling processes

Industry insights, straight to your inbox

- Stay up to date with the latest industry trends.

- Exclusive insights and practical advice from industry experts.

- Keep ahead of legislative changes impacting your business.