Enhance flowline manufacturing in aerospace with electric tugs

Aerospace manufacturing encompasses an array of manufacturing environments and disciplines from metal shops and composite manufacturing to large-scale final assembly facilities.

Large commercial aircraft can consist of up to 5 million manufactured parts, all produced to the highest standards through a tiered production system. The volume of parts involved and the need for specialisation and scalability mean that the production of aircraft often involves a flowline system utilising sub-assemblies.

Flowline processes in practice

A rear fuselage assembly (which in itself is composed of multiple parts and sections) is transferred to a sub-assembly area of the plant. From here, sub-assemblies are fitted to support jigs and systems, increasing in size and weight as additional parts and sections are added at the various workstations.

The same process is true for other sub-assemblies such as wing sections, additional areas of fuselage and tail or empennage sections. These various sub-assemblies are then transported using just-in-time (JIT) techniques to the final assembly line (FAL) ready for the final build.

Transportation & movement challenges

Throughout a staged production process, sub-assemblies increase in weight and size as more materials and sections are added, presenting a challenge when it comes to moving them through the production flow.

Depending on the parts being moved, transportation of heavier sections is often achieved through the use of overhead cranes, forklift trucks or large transfer trolleys. For smaller parts and sections, some facilities rely on manpower and manual handling to manoeuvre sections through production stages.

Traditional transportation methods present several challenges for aerospace manufacturers, whether in the movement of fuselage sub-assemblies or the final assembly stages of aircraft.

The benefits of staged, flowline production systems are often disrupted by downtime waiting for a licensed forklift driver to mobilise heavy loads. This can cause bottlenecks in flowline systems and reduce operational efficiency.

Similarly, relying on overhead cranes for sub-assembly transfers can also cause delays and, where multiple cranes are installed, an overlap of routes can lead to wasted time in waiting for other cranes to clear an area. Overhead cranes can also restrict production layout due to their fixed design and mechanical issues can cause severe delays in the production process.

Finally, remote-controlled transfer trolleys are typically a cumbersome option, which can be difficult to precisely position within aerospace manufacturing environments. This, coupled with the risk of complete bottlenecks in the event of a breakdown, is leading many manufacturers towards a more modular solution in industrial electric tugs.

Powerful, lean, and flexible solutions

Aerospace electric tugs offer an alternative to traditional aerospace material handling methods and deliver considerable efficiency gains in the form of time savings, flexibility, and process improvement for aerospace manufacturers.

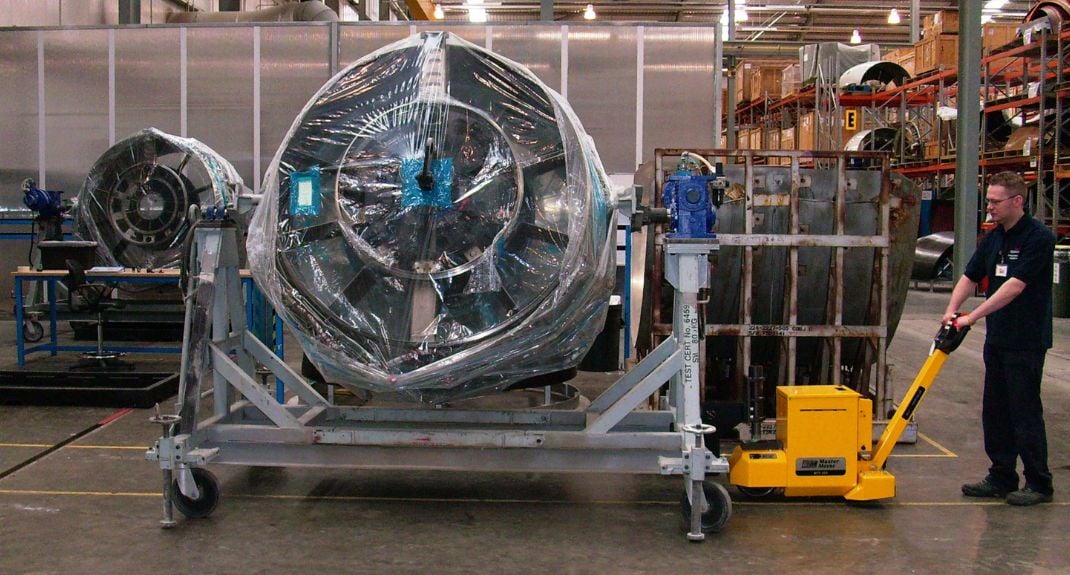

Suitably powered to move even the heaviest loads within the aerospace industry, our industrial electric tugs enable a single operator to carefully position, and manoeuvre loads of over 70,000kg.

Manufacturers need aerospace handling solutions that help support robust and lean production processes. With a license-free operation, industrial electric tugs remove bottlenecks and any downtime in waiting for licensed forklift drivers or crane operatives, whilst also providing a safer alternative for use in congested areas. Where transportation was previously carried out manually, electric tugs mean staff are freed up to carry out value-adding activities and critical production tasks.

With a design focused on scalability, manufacturers can utilise industrial electric tugs and tows on a range of applications as required. Working alongside a flowline system, electric tugs deliver flexibility and allow manufacturers within the aerospace industry to scale production up or down as needed.

Easy integration to deliver flow

Electric tugs can be seamlessly integrated into existing processes without the need for infrastructure overhauls or complex installations.

Facilitating the controlled movement of sub-assemblies, industrial electric tugs quickly help manufacturers realise the real-world benefits of efficient flowline processes. This, coupled with a design focused on easy integration with common aerospace manufacturing equipment make electric tugs an attractive option for aerospace manufacturers.

Having provided powerful, compact electric tugs to most of the world’s largest aerospace assembly plants for 25 years, we’ve developed a proven track record of delivering tangible process improvements for flowline production systems.