The Dangers of Moving Loaded Bins by Hand

The age-old adage, "Safety first," rings especially true in workplaces that involve the movement of heavy loads and equipment, ranging from automotive manufacturing to logistics. But, for many years, the manual movement of heavy bins has been an accepted practice.

However, as we'll explore in this blog, this approach poses significant safety risks, inefficiencies, and challenges for facilities staff.

The Risks of Moving Loaded Bins

Manual movement of loaded bins is not just strenuous, but dangerous as well. Workers often underestimate the risks associated with such activities.

Overexertion has been reported as a leading cause of workplace injury in recent years, with thousands of cases resulting in days away from work or job restrictions. Manual handling of heavy loads, such as loaded bins, significantly contributes to these numbers.

Heavy lifting and twisting motions can lead to a range of health issues including back injuries, hernias, and muscle strains. Moving waste bins by hand also increases the risk of crush injuries, should the bin tip or roll unexpectedly.

37% Upper limbs or neck

21% Lower limbs

42% Back

HSE reports that the key work factors causing work-related MSDs are:

Manual handling

Working in awkward or tiring positions

Repetitive movements

Efficiency Takes a Hit

Efficiency and safety often go hand in hand. When tasks are more dangerous, they tend to be slower, with workers taking additional precautions.

The manual movement of heavy loads often requires multiple personnel, slowing tasks down. Using two or more employees to move a single bin is not an optimal use of resource, as the job takes longer and pulls workers away from other essential tasks.

The Added Complexity of Slopes

Moving heavy loaded bins on slopes presents an even more significant challenge.

Slopes - even slight ones - amplify the force needed to start, hold, and stop movement. The force required to prevent a bin from rolling down an incline can be many times that required on a flat surface. Given that a fully loaded waste bin can weigh several hundred kilograms, the risks become significant.

On a sloping surface, a minor misjudgment or slip can lead to a runaway bin. The potential for injury in such scenarios is vast, not just for the workers involved, but for anyone in the path.

Furthermore, trying to halt a heavy bin's momentum can strain muscles and joints, increasing the risk of acute injuries.

The Hidden Costs of Injuries

Beyond the immediate harm to employees, workplace injuries carry hidden costs that many businesses overlook. Worker compensation claims can be expensive, but they're just the tip of the iceberg.

There's also the matter of lost productivity, possible legal action, increased insurance premiums, and the cost of hiring or training replacement staff. Injuries can also affect team morale, leading to reduced enthusiasm and dedication among the staff.

In the UK, 7.3 million working days are lost due to work-related musculoskeletal disorders. Meanwhile in the US , workplace injuries and illnesses cost businesses over $170 billion each year.

A significant proportion of these numbers can be attributed to manual handling injuries, such as those that can occur from moving heavy waste bins and containers by hand.

Embracing Manual Handling Solutions in Bin Movement

The challenges of the modern workplace require modern solutions. Relying on old methodologies, especially in the realm of safety, is a recipe for inefficiency and potential risk. Technological advancements have brought forth tools designed specifically to address challenges like moving heavy waste bins.

As passionate advocates for workplace safety and efficiency, we understand the need for better solutions.

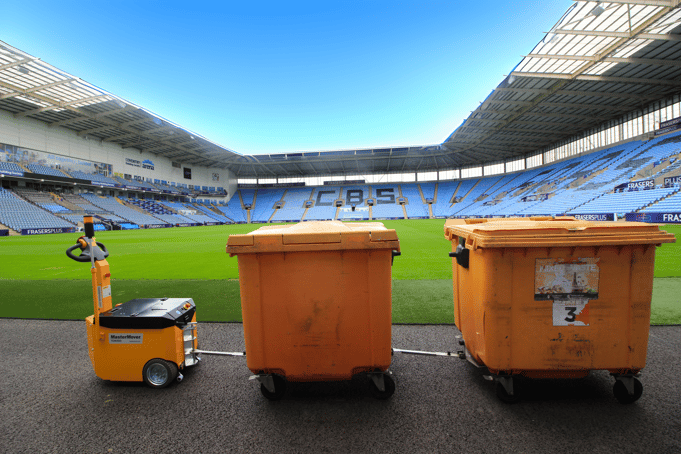

That's where our battery powered bin moving electric tug machines come in…

Safer Movements with Powered Solutions

Designed to allow a single person to easily and safely move heavy bins, our electric tugs are simple to operate, connect securely to the bin being moved, and are packed with safety features.

Our powered bin movers are the ideal solution to move heavy waste bins, improve safety in facilities management and boost staff productivity.

Conclusion: The Time for Change is Now

Workplace safety is not just a matter of regulatory compliance; it's about creating a culture where employees feel valued and protected. The risks associated with manually moving bins, especially on slopes, are clear and present. Solutions like our BinMover offer an answer, blending safety with efficiency.

Companies that proactively address these risks not only protect their most valuable asset—their employees—but also position themselves for increased productivity and profitability. It's time to embrace the tools and strategies that reflect the demands and responsibilities of today's business landscape.