Automated Guided Vehicle Applications & Examples

AGV Systems

Automated Guided Vehicles (AGVs) are revolutionising industrial operations by providing autonomous transportation solutions across a diverse range of sectors, but what are some of the most common AGV applications?

Thank you for your request to download the MasterMover 'Guide to Autonomous Guided Vehicles'.

We'll also send you an email shortly with your download link included for safe keeping.

If you do not receive the email, please let us know at salesteamuk@mastermover.com.

Thank you for your request for an AGV System Consultation!

One of our representatives will be in touch with you shortly to discuss your request in more detail.

.jpg?width=952&height=674&name=AGV_Still-1.18-Image_1200x800px%20(1).jpg)

What are AGVs?

AGVs, or Automated Guided Vehicles, are autonomous vehicles used for material handling tasks in various industries such as manufacturing, warehousing and logistics. AGVs work with sensors, navigation systems and safety scanners to navigate through a facility without human intervention. AGVs navigate using two main forms of navigational systems, line follow and natural feature navigation.

They can transport materials, goods, or products from one location to another within a facility following predefined routes. They are designed to improve efficiency, reduce labor costs, enhance safety, and optimise material handling operations

What are the Benefits of AGVs?

For industrial manufacturers and warehouse operations, the adoption of AGVs has been forecast to skyrocket for over a decade, with AGV systems offering a multitude of benefits.

By leveraging AGVs, companies experience improved operational efficiency, enhanced safety, increased productivity, reduced human error and cost savings. The repeatability of AGV systems and their ability to deliver greater accuracy than manually guided vehicles (MGVs) is also driving interest across other industries such as pharmaceutical, healthcare and food manufacturing.

Manufacturers Set to Increase AGV Adoption

The market for Automated Guided Vehicles is in a high growth stage, with adoption still increasing year-on-year as businesses look to benefit from greater efficiency and streamlined processes. As we delve into a handful of specific AGV applications, it becomes evident how AGVs play a crucial role in reshaping and optimising industrial processes.

AGV Applications in Manufacturing

AGVs excel in enhancing material handling processes within manufacturing facilities by efficiently transporting raw materials, work-in-progress items, and finished goods.

Streamlining the movement of materials throughout the manufacturing process, AGVs optimise workflows to drive operational efficiency.

AGVs and AMRs are utilised across industrial manufacturing sectors, but implementations are typically most effective in repeatable processes like those seen in automotive manufacturing and heavy plant machinery assembly.

-

Types of AGV in Manufacturing

There are various types of AGVs available, but the nature of manufacturing and assembly processes mean that towing AGVs and unit load AGVs tend to be the most popular type of AGV used within the industry, closely followed by AGV forklifts.

-

AGV Use Cases in Manufacturing: Material Movement

Within manufacturing, AGVs tend to be utilised on critical, but repetitive supporting tasks, such as towing mother-daughter carts and raw materials to production lines, transferring work-in-progress parts through production stages and moving finished products off the line.

All of these tasks are critical to the assembly process, but across these applications, the AGV is supporting the process.

-

AGV Use Cases in Manufacturing: Production Lines

The second main way that AGVs can be utilised in industrial manufacturing is in becoming the system that drives, or powers, the production line.

Increasingly, manufacturers are looking to move away from traditional chain driven production lines and conveyors, turning their attention to AGVs to power their production line.

In this type of use case, automated guided vehicles are used as the production line, moving products through the various assembly stages.

-

Benefits of AGVs in Manufacturing

In manufacturing, AGVs not only optimise material flow but reduce manual labor and streamlining operations, freeing up staff to work on more productive tasks.

Through the integration of AGVs, facilities can achieve faster and more efficient workflows, enabling just-in-time manufacturing and supporting lean principles for flexible production.

Whether they’re used to support the production process, or to power assembly lines, AGVs deliver a flexible, scalable and reliable solution for manufacturers.

Toyota accelerates efficiency with an AGV system

A world leader in its field, the automotive manufacturer has achieved return on investment and improved operational efficiency when moving parts to the production line.

See how Toyota Motor Manufacturing used an AGV system to automate its driving processes.

AGVs for Heavy Load Transportation

For industries such as heavy plant manufacturing, aerospace, energy, and defence sectors, manufacturing processes often involve the movement of heavy parts, work-in-progress, sub-assemblies and finished products. For these manufacturers, payloads can often range from 10,000kg right up to 30,000kg and beyond – which can make finding an automatic guided vehicle solution difficult.

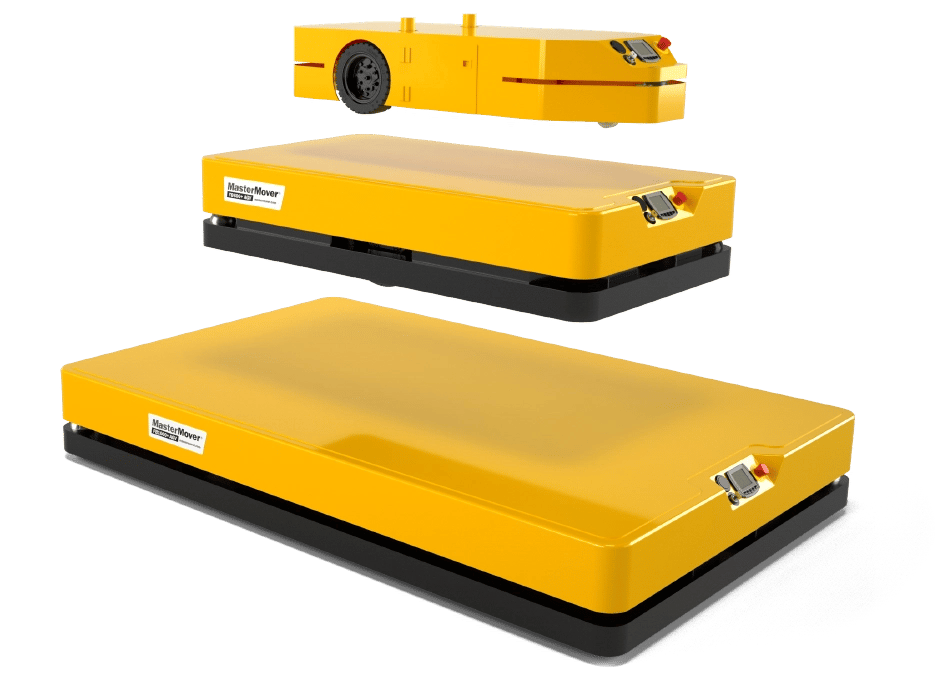

In this realm, heavy-duty unit load AGVs are becoming the machine of choice for heavy load transportation, alongside towing AGVs with heavy payloads capabilities. By improving material flow and enhancing handling operations even with the heaviest of loads, heavy-duty AGVs optimize intralogistics processes and drive operational efficiency.

The ultimate guide to AGV electric tugs

Automated Guided Vehicles (AGV)

Looking to understand Automated Guided Vehicles in a little more detail?

We’ve compiled some helpful resources to get you started, covering everything you need to know.

Warehouse AGV Use Cases

Within warehouse and logistics environments, AGVs are typically used for transporting pallets and palletised goods. AGV pallet trucks and AGV forklifts are typically used to palletise and depalletise goods, minimising manual effort and time, while their advanced navigation technologies ensure safe and efficient movement within busy warehouse environments.

Towing AGVs can also be found within such settings, often used to tow trains of carts in fulfilment centres to enhance warehouse productivity and order picking efficiency.

Conclusion

Automated guided vehicles offer a versatile and efficient solution to modern-day operational challenges. The unparalleled benefits of utilising AGVs underscore their role in shaping the landscape of industrial operations across a diverse range of industries and applications.

We're here to help

If you’re looking to improve safety, remove the risk of injury and unlock greater operational efficiency, we’re here to help. Speak to our team to discuss your application.