Fully Autonomous Load Moving

Drive ROI, safety and operational efficiency with AGV solutions

Thank you for your request to download the MasterMover 'Guide to Autonomous Guided Vehicles'.

We'll also send you an email shortly with your download link included for safe keeping.

If you do not receive the email, please let us know at salesteamuk@mastermover.com.

We may contact you by phone or email, if you have not opted out, or where we are otherwise permitted by law, to provide you with marketing communications about similar goods and services. The legal basis that allows us to use your information is ‘legitimate interests’. More information about how we use your personal data can be found in our Privacy Policy.

Thank you for your request for an AGV System Consultation!

One of our representatives will be in touch with you shortly to discuss your request in more detail.

We may contact you by phone or email, if you have not opted out, or where we are otherwise permitted by law, to provide you with marketing communications about similar goods and services. The legal basis that allows us to use your information is ‘legitimate interests’. More information about how we use your personal data can be found in our Privacy Policy.

Automated Guided Vehicles

Automated Guided Vehicles (AGVs) have the ability to be transformational when it comes to driving operational efficiency within industrial manufacturing. Featuring best-in-class navigation and safety technologies, AGVs remove the need for human operation, carrying out movement of products, equipment and materials on time, every time.

This not only makes the operation more efficient but protects your people from the stresses and injuries associated with manual handling, or higher risk load moving solutions. Furthermore, it also means your people can focus on tasks of greater value, driving additional ROI and efficiency.

AGV in Action: Toyota

Learn how Toyota Motor Manufacturing used an AGV system to automate its driving processes.

A world-leader in its field, the automotive manufacturer has achieved return on investment and improved operational efficiency when moving parts to the production line…

Navigation and machines you can trust

All our AGVs feature BlueBotics best-in-class Autonomous Navigation Technology. With over 20 years’ proven technology experience working in over 4,500 products and driving over 10 million km, they are trusted by leading companies around the world. MasterMover’s high performance product range means the benefits of our partnership provides you a robust AGV solution which you can trust to deliver your ROI in the future.

We may contact you by phone or email, if you have not opted out, or where we are otherwise permitted by law, to provide you with marketing communications about similar goods and services. The legal basis that allows us to use your information is ‘legitimate interests’. More information about how we use your personal data can be found in our Privacy Policy.

We may contact you by phone or email, if you have not opted out, or where we are otherwise permitted by law, to provide you with marketing communications about similar goods and services. The legal basis that allows us to use your information is ‘legitimate interests’. More information about how we use your personal data can be found in our Privacy Policy.

AGV electric tugs by range

MasterTow AGV Range

Up to 20,000 kg

MasterTow AGVs as the name suggests, are perfectly designed for towing multiple loads at once with scalable autonomous connecting.

Featuring full natural navigation, they are programmed to integrate with your existing environment such as shutter doors and traffic light systems, for safe, efficient operation.

Thank you for your interest!

Your requested technical datasheet can be accessed via the button below. A copy has also been sent to you via email.

Please contact us with any questions regarding our products and services, or book in some time to speak with a member of our team.

We may contact you by phone or email, if you have not opted out, or where we are otherwise permitted by law, to provide you with marketing communications about similar goods and services. The legal basis that allows us to use your information is ‘legitimate interests’. More information about how we use your personal data can be found in our Privacy Policy.

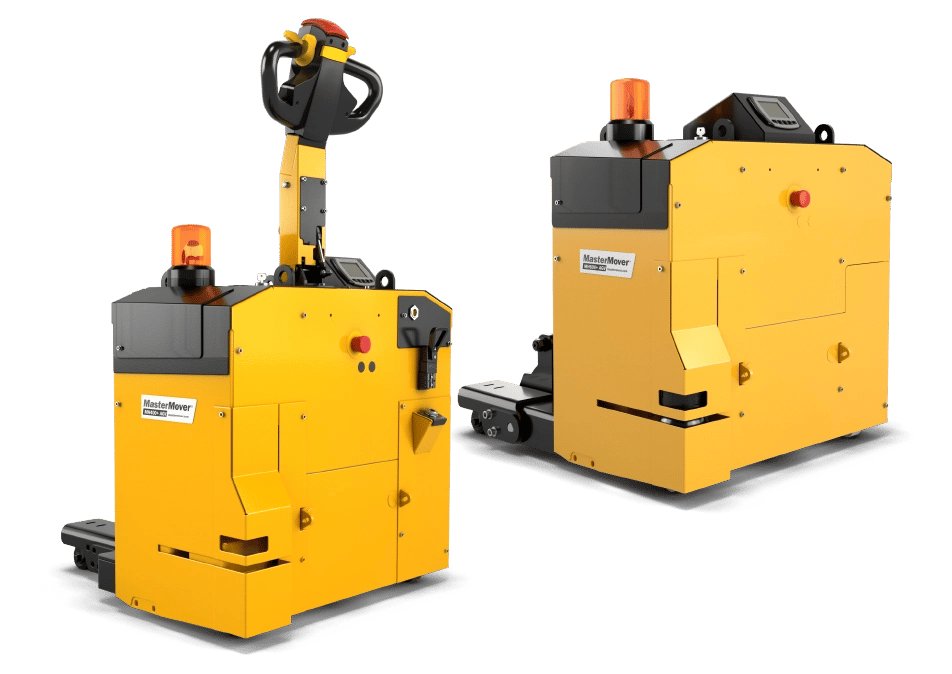

MasterHandler AGV Range

Up to 6,000 kg

MasterHandler AGVs, despite their compact size are capable of powerful load moving performance.

With full natural navigation and compact dimensions, every model is able to perform precise movements, making them ideal for busy and congested environments like modern factories, where safety and efficiency is paramount.

Thank you for your interest!

Your requested technical datasheet can be accessed via the button below. A copy has also been sent to you via email.

Please contact us with any questions regarding our products and services, or book in some time to speak with a member of our team.

We may contact you by phone or email, if you have not opted out, or where we are otherwise permitted by law, to provide you with marketing communications about similar goods and services. The legal basis that allows us to use your information is ‘legitimate interests’. More information about how we use your personal data can be found in our Privacy Policy.

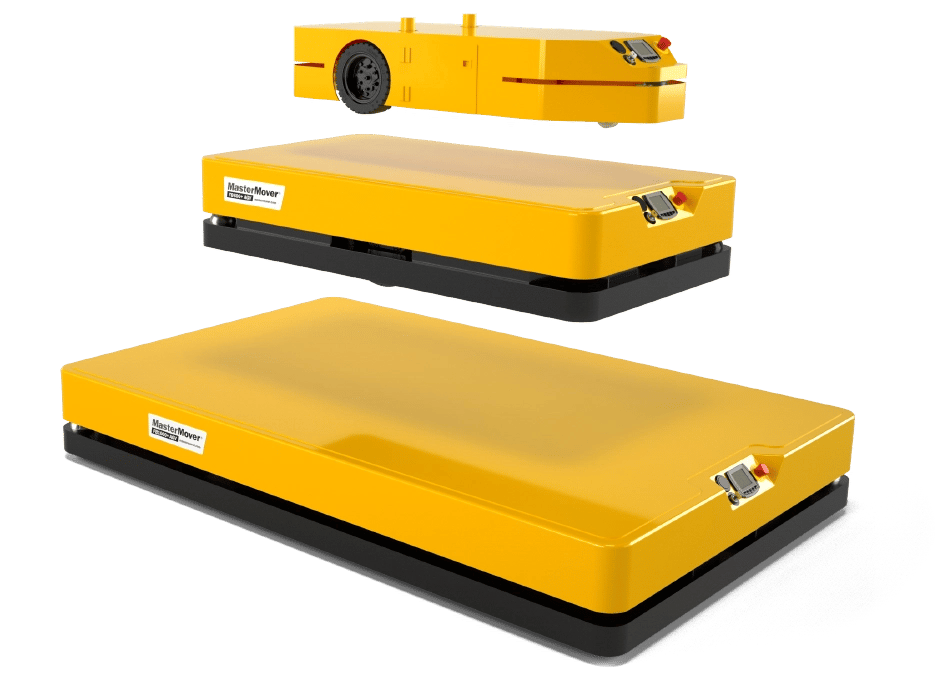

FlatBed AGV Range

Up to 10,000 kg

Unlike some of our competitor’s large and cumbersome units, our FlatBed AGVs are quality load carriers that are built to last.

These AGVs are highly manoeuvrable and can pivot on the spot, making them ideal for working in tight spaces. Seamless integration enables ultimate efficiency and safety in any environment.

Thank you for your interest!

Your requested technical datasheet can be accessed via the button below. A copy has also been sent to you via email.

Please contact us with any questions regarding our products and services, or book in some time to speak with a member of our team.

We may contact you by phone or email, if you have not opted out, or where we are otherwise permitted by law, to provide you with marketing communications about similar goods and services. The legal basis that allows us to use your information is ‘legitimate interests’. More information about how we use your personal data can be found in our Privacy Policy.

PowerSteered AGV Range

Up to 70,000 kg

Our PowerSteered AGVs are trusted by industrial manufacturers to deliver the autonomous movement of the heaviest payloads.

Your choice for heavy weight AGV capabilities, the PowerSteered AGV range drives efficiency and repeatable processes across heavy industry.

We may contact you by phone or email, if you have not opted out, or where we are otherwise permitted by law, to provide you with marketing communications about similar goods and services. The legal basis that allows us to use your information is ‘legitimate interests’. More information about how we use your personal data can be found in our Privacy Policy.

We may contact you by phone or email, if you have not opted out, or where we are otherwise permitted by law, to provide you with marketing communications about similar goods and services. The legal basis that allows us to use your information is ‘legitimate interests’. More information about how we use your personal data can be found in our Privacy Policy.

Built with benefits to supercharge your processes

Increased Return on Investment

AGVs deliver greater ROI through increased efficiency and safety, better use of people resources, less risk of mechanical failure and greater flexibility.

Maximum Safety Built-In

With in-built safety systems, environmental scanners, and optimum surrounding awareness – increased safety comes as standard.

Efficiency Supercharged

Drive operational efficiency by carrying out tasks on time and at the optimal speed. Enjoy flexible layouts without the constraints of fixed infrastructure.

Scalable Pulling Power

Our Automated Guided Vehicles are available with a capacity up to 30,000kg, enabling automated movement of even the heaviest of loads.

Delivering return on investment

An AGV can reach an ROI of between 50% and 150% when used for a single-shift over 3 years.

This can be dramatically increased to over 600% when the machine is used as part of a three-shift operation over a 5-year period.

An AGV that fits your application

Regardless of your current phase, we understand that switching to an AGV is an investment, even if it is one that will inevitably deliver increased ROI, efficiency and safety. Our skilled and experienced team is here to guide you with our tried and tested approach.

Our 5-step process:

Thank you for your request to download the MasterMover 'Guide to Autonomous Guided Vehicles'.

We'll also send you an email shortly with your download link included for safe keeping.

If you do not receive the email, please let us know at salesteamuk@mastermover.com.

We may contact you by phone or email, if you have not opted out, or where we are otherwise permitted by law, to provide you with marketing communications about similar goods and services. The legal basis that allows us to use your information is ‘legitimate interests’. More information about how we use your personal data can be found in our Privacy Policy.

-

1. The right machine for you

Firstly, we put time into understanding your application.

-

2. The right navigation for your site

We’ll explore which navigation system works best.

-

3. The right dispatch commands

Next, our team will look at how the AGV gets its instructions to move or ‘pulse’ to the next location.

-

4. Integration with your systems

Then, we look at where other system integrations are needed.

-

5. Optimise your safety systems

Depending on the environment and application, identifying the right safety systems is key.

The ultimate guide to AGV electric tugs

Automated Guided Vehicles (AGV)

Looking to understand Automated Guided Vehicles in a little more detail?

We’ve compiled some helpful resources to get you started, covering everything you need to know.

Why we're different. Our AGV capability

Weight Capacity

Move up to 30,000kg, enabling automated movement of even the heaviest of loads.

Speed

MasterMover AGVs travel up to 2.5m per second even with heavier loads.

Terrain

Designed to travel inside, outside, in the rain, and even on slopes.

Durability

All MasterMover products are manufactured to the highest standards, meaning they are reliable, durable and dependable.

Dual Mode

Easily be utilised for other tasks and jobs, helping drive additional ROI and flexibility.

Intelligence

Our AGV does not rely upon WiFi like many other AGVs to operate.

Battery Capacity

With a runtime of 10 hours, and 24 hours using multiple batteries. Operational efficiency is maximised.

Custom Solutions

Our in-house team can design and build entire custom solutions, in stainless steel, and to ATEX and IP55 standards if required.

We may contact you by phone or email, if you have not opted out, or where we are otherwise permitted by law, to provide you with marketing communications about similar goods and services. The legal basis that allows us to use your information is ‘legitimate interests’. More information about how we use your personal data can be found in our Privacy Policy.

We may contact you by phone or email, if you have not opted out, or where we are otherwise permitted by law, to provide you with marketing communications about similar goods and services. The legal basis that allows us to use your information is ‘legitimate interests’. More information about how we use your personal data can be found in our Privacy Policy.

Answering your AGV questions

For many people, AGVs are still unknown and so it’s no surprise that people ask “What is an AGV?'.

Sometimes referred to as autonomous guided vehicles, automated guided vehicles (AGVs) are a type of material handling system that travel autonomously - without the need for an operator or driver. As a self guided vehicle, they improve efficiency and material flow by automating repetitive tasks. A range of different types of automatic guided vehicles exist including forklift AGV systems, towing AGV and tugger AGV systems, unit load AGVs, automated guided cart systems and automated load carriers.

A towing AGV system enables businesses across industrial manufacturing and logistics to drive operational efficiency, increase resource utilisation and reduce non-value adding tasks in their material handling processes.

With the rise in industrial automation, many businesses look to automatic guided vehicles to streamline the movement of heavy materials and loads, eliminating the need for human involvement.

If you're interested in an automated guided vehicle system or autonomous vehicles, you're probably wondering what industries use them. Automation and automated equipment is becoming increasingly more accessible and adoption of automated technologies is no longer just seen in automotive environments.

Our AGV systems are used across industrial manufacturing, from plastics and metal manufacturing to automotive assembly.

Likewise, the repetitive nature of intralogistics processes in distribution and logistics continues to drive an increase in warehouse automation systems and automated guided vehicles.

Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) differ primarily in their navigation capabilities.

AGVs rely on pre-defined routes or markers to follow a fixed path within a controlled environment, requiring physical infrastructure for guidance. In contrast, an autonomous mobile robot utilises advanced sensor systems and algorithms to autonomously navigate without the need for fixed infrastructure or predetermined routes.

AMRs can perceive their surroundings, avoid obstacles, and dynamically plan paths in real-time. AMRs are most commonly used to move lighter loads, with the most common design being a unit carrier or load carrier.

Our advanced AGVs feature best-in-class Autonomous Navigation Technology (ANT) by BlueBotics. ANT natural navigation requires no external infrastructure. Using sensors, the AGV maps its surrounding, during training, resulting in no need to reconstruct warehouse or production environments.

The different types of AGVs and their corresponding navigational methods dictate the ease of installation. For example, a line following system, an AGV system in its’ most simplistic form, enables simple cost-effective installation by simply sticking a line of tape that the machine follows.

For more complex systems, a reputable supplier will work with you to arrange installation at your site.

Our AGV integrates sensors and various components that receive, process and analyse data in real time and act accordingly. When an autonomous guided vehicle encounters an obstacle on its route, such as a pallet or person, it will stop if it detects that it could harm the operators.

AGV perfectly complements your existing workforce. AGVs do the heavy manual work, Removing or reducing the need for your staff to move materials, allowing your people to spend more time doing greater-value tasks.

Our AGV navigation technologies include:

Line follow: A painted or magnetic line on the floor.

The AGV follows only the painted or magnetic line (including markers to tell it where to stop or change direction).

Natural: A navigation that requires no external infrastructure.

The AGV maps its surroundings using sensors during training runs, and stores the data onboard.

Our AGVs, unlike others, are built to operate indoors, outdoors, on slopes, uneven terrain and even in the rain, ensuring production and manufacturing processes can reduce downtime with autonomous load moving between buildings.

MasterMover AGVs travel up to 2.5m per second, even with a heavy load. AGVs are capable of adapting to the surrounding environment, slowing down at certain points i.e. through high pedestrian areas and then speeding up when necessary.

Ready to talk? Request a consultation

We may contact you by phone or email, if you have not opted out, or where we are otherwise permitted by law, to provide you with marketing communications about similar goods and services. The legal basis that allows us to use your information is ‘legitimate interests’. More information about how we use your personal data can be found in our Privacy Policy.