Custom Tug Success For Leading Petrochemical Plant

Leading petrochemical plant works with MasterMover to develop 43 custom electric tugs for use within challenging and hazardous conditions.

MasterMover was approached by Fluor, a world leading engineering and construction company, to design and build a custom solution that could safely move highly-sensitive and awkward loads at Tengiz oilfield in Kazakhstan.

Recognising the need to partner with a reputable provider who was experienced in working within the petrochemical industry, Fluor chose to collaborate with MasterMover.

Project summary

- Industry challenges: In the energy industry, there is a need for load moving solutions that can work in compact areas, around tight corners, at height and over tricky flooring – all whilst still delivering outstanding safety and efficiency gains.

- Project plan: Led by a dedicated Project Manager and Mechanical Design Engineer, MasterMover developed a modified electric tug – one that was cleverly adapted to the stringent demands of a particular and unique working environment.

- Solution delivery: Despite the short lead time for the design and production of a new product, the MasterMover team delivered ahead of schedule – meeting every single requirement along the way.

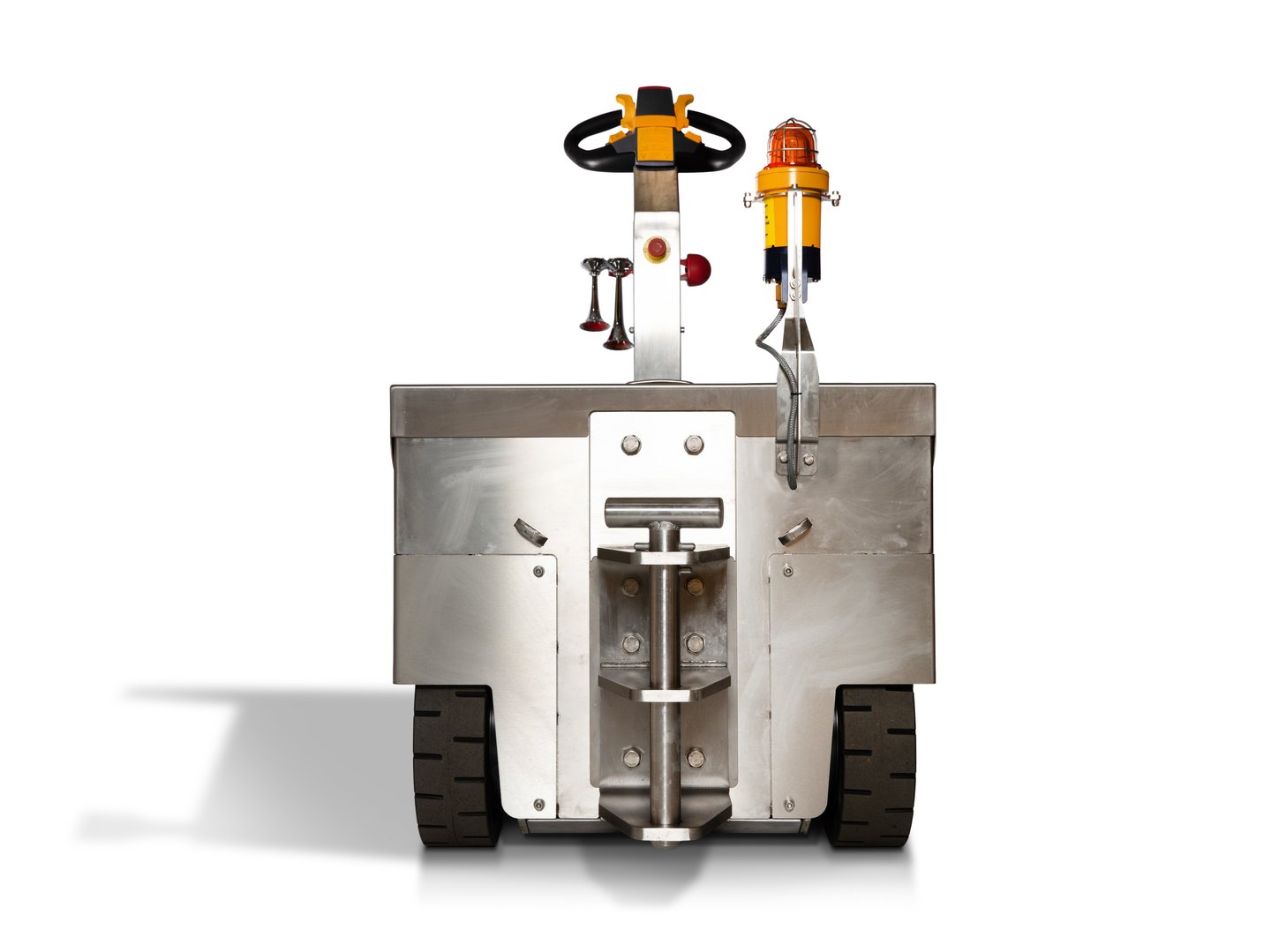

- Product requirements: new stainless steel machines needed to be specially treated to comply with the ATEX Zone 1 and EAC directives and as such, had to be suitable for use in areas where there was a risk of potential explosion.

Exploring all options

Fluor invited different material handling companies to take part in a tendering process, scrutinising alternative load moving methods including overhead cranes, winches, and motorised skates.

All were rejected on the grounds of safety and efficiency concerns with a key specification being that the eventual solution needed to be able to move a load of 5,000 kg across grating and around tight corners using client specified trolleys.

A modified electric tug was the only answer – albeit one that was cleverly adapted to the stringent demands of a particular and unique working environment. In addition, the client needed to be confident about working with a company that had the design and engineering project management capabilities to deliver a bespoke order of this magnitude.

The overall project deliverables were constrained by a rigorous client documentation pack, the need to adhere to strict international standards and a demanding timeline.

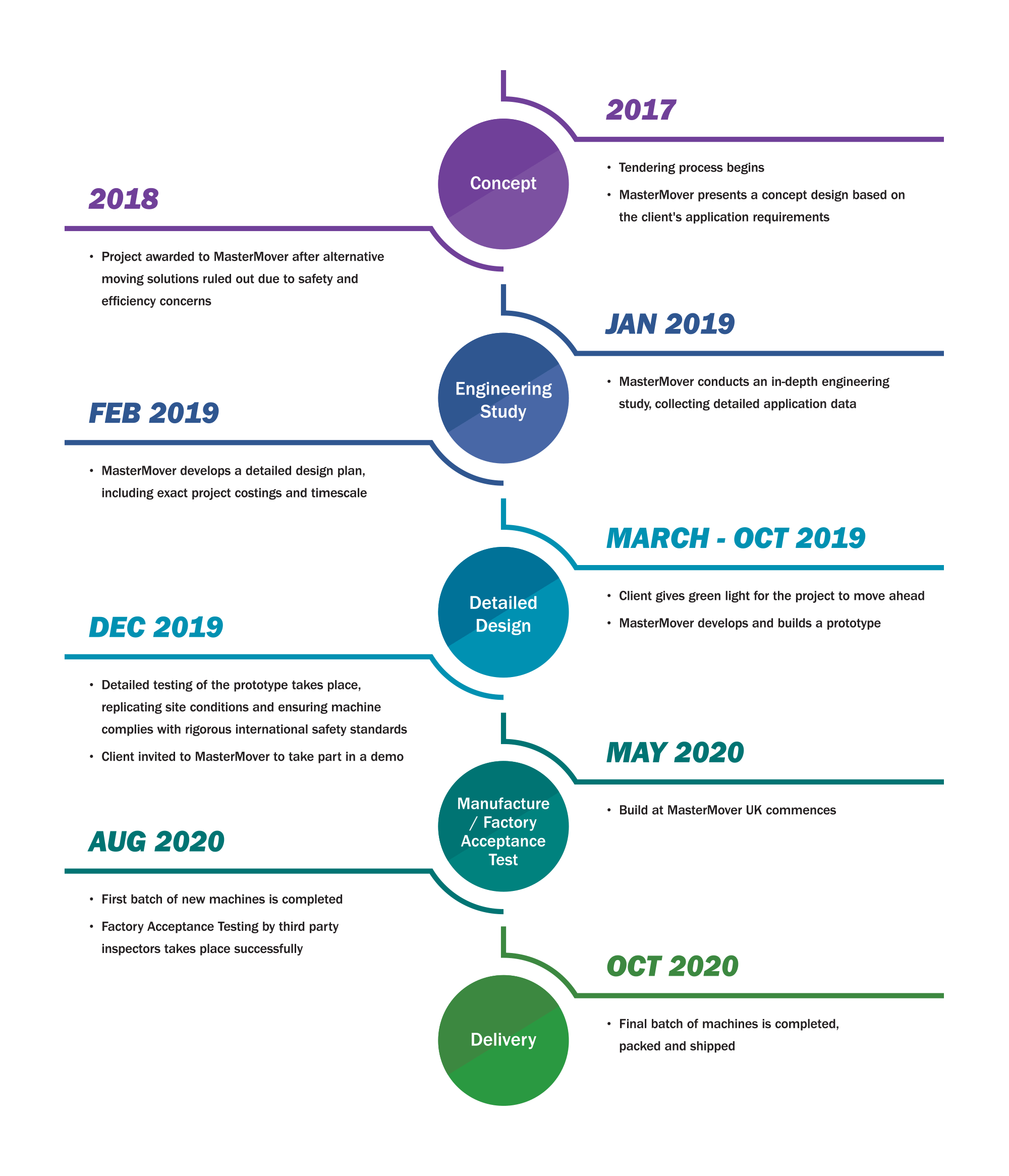

Project timeline

The plan

Led by a dedicated Project Manager and Mechanical Design Engineer, an in-depth engineering study was required to collect detailed application data. This had to take into consideration a number of defined turns of various width and tightness.

The study allowed MasterMover’s Special Projects team to develop a prototype. Working alongside Pyroban, a specialist provider of ATEX conversions, the prototype was based on the most challenging load moving task faced. It would also ensure the new machines would work in a potentially explosive environment.

ATEX conversion is a complex and time-consuming process, requiring every single electrical component within the body of a machine to be stripped back and re-engineered separately before being brought back together during assembly.

The prototype, which was a modification of an existing MasterMover MasterTow, validated the integration of the electrical enclosure into the machine body through a number of thermal tests in accordance with ATEX Zone 1 restrictions.

After a successful client demonstration at MasterMover around a simulated course on site-specific flooring, production was ready to commence. As build was towards the end of the project schedule – with potential financial penalties for even a delay of 24 hours – speed and accuracy was of the essence.

To minimise any potential for delay and disruption, a new just-in-time production layout was created at MasterMover’s manufacturing headquarters in Derbyshire. Meanwhile, an already highly skilled MasterMover production team undertook additional ATEX training.

Specialist assembly tools and jigs were designed and manufactured specifically for the build process. These included a support frame to hold the partially wired ATEX enclosure above the main machine carcass during assembly, and a motor-loading trolley (which the client would go on to use for the subsequent maintenance of the machines).

Batch production allowed third party inspectors to visit at regular points to check that the client’s expectations and international standards were being met throughout.

As well as the 39 bespoke machines, Fluor also ordered 4 stainless steel MasterTugs, spare parts, and couplings.

Custom petrochemical solutions

The result

Despite the short lead time for the design and production of a new product, the MasterMover team delivered ahead of schedule – meeting every single requirement along the way.

The completed project is now attracting interest from around the world, as well as other manufacturing sectors.

The eventual solution needed to be able to move a load of 5,000 kg across grating and around tight corners using client specified trolleys.

James Jones. Special Project DirectorMasterMover

Thanks to the combination of safety-first features and power, it is now possible to keep employees protected from the dangers of flammable vapours and still harness the load moving capabilities of a MasterMover.

This bespoke solution is the latest in an innovative range of electric tugs and tows that are used by many different industries to improve productivity, create smoother workflows, and reduce non-value-added activities.

MasterMover designs and manufacturers innovative electric tug solutions to solve complex material handling problems. Alongside our standard product offerings, we're equipped to deliver custom solutions and special projects that meet the unique needs of different applications.