What are Automated Guided Vehicles?

AGV Systems

Thank you for your request to download the MasterMover 'Guide to Autonomous Guided Vehicles'.

We'll also send you an email shortly with your download link included for safekeeping.

If you do not receive the email, please let us know at salesteamusa@mastermover.com.

Thank you for your request for an AGV System Consultation!

One of our representatives will be in touch with you shortly to discuss your request in more detail.

What is an AGV?

An automated guided vehicle (AGV) is a material handling system that travels autonomously without the need for an operator. With AGVs delivering significant efficiency gains, manufacturers across a range of industries are increasingly adopting the technology to mobilize their operations. Across the manufacturing industry, the term AGV has become a buzzword, but what are they and how do automated guided vehicles work?

With the increasing interest in AGVs and Industry 4.0 technologies, we’ve put together this quick guide to equip you with the knowledge to understand what an AGV system is and the benefits they can deliver.

Different types of AGV system and how they work

There are several different types of automated guided vehicles which are typically split by the navigational method they use.

The most common navigation systems can be split into two categories:

Line follow

Line follow AGVs navigate and follow a defined path that can be specified by the operator. Line follow capabilities make sure AGVs follow the same route time after time, even when working in tight spaces or moving loads through areas with minimal clearance.

Barcodes can also be placed on the ground, or other similar identifiable prompts, for the machines to scan for additional programmed information, such as slowing down through a specific area. This makes the environment safer and reduces the risk of damage to high-value loads, the premises, and people.

Natural navigation

The most sophisticated form of AGV, natural navigation machines use sensors and scanning systems to navigate autonomously by detecting and mapping the environment around them to move around obstacles.

The sensors ensure a programmed response to any detected risk and the units will stop until the hazard has been moved away.

8 benefits of AGV systems

Now you understand the differences and types of AGV technology available, the next question you’ve probably got is “What are the benefits of an AGV system?”.

From delivering repeatable movements to increasing safety within congested production environments, AGV systems can provide an array of benefits for industrial manufacturing environments.

Thank you for your request to download the MasterMover 'Guide to Autonomous Guided Vehicles'.

We'll also send you an email shortly with your download link included for safekeeping.

If you do not receive the email, please let us know at salesteamusa@mastermover.com.

-

1. AGVs improve efficiency and throughput

Without the need for an operator, AGV systems dramatically reduce bottlenecks and downtime associated with waiting for licensed drivers or operators.

-

2. They deliver consistent movements

Automated guided vehicles deliver repeatable movements, every time. This delivers safe, precise movements by removing room for human error.

-

3. They reduce labor time

Freeing up employees for value-adding tasks helps you make better use of your people and address potential labor shortages.

-

4. They lower costs

They deliver a greater return on investment by optimizing's people resources and facilitating a 24/7 operation.

AGV systems can also help to reduce accidents and injuries, which can lead to lower insurance premiums and compensation claims.

-

5. They’re flexible and scalable

Can be easily switched to a manual operation mode to move any wheeled load within its weight capability. This enables them to complete a wider range of tasks, delivering a flexible solution that allows you to scale up or down operations as needed.

-

6. They’re safe

AGVs are equipped with collision avoidance sensors and extensive safety systems to keep people, products, and plant equipment safe.

-

7. They’re customizable

They can be fully customized to fit the specific needs of your processes and operations.

-

8. They’re environmentally friendly

They are emissions-free and help reduce noise pollution and as they’re 100% electric.

The ultimate guide to AGV electric tuggers

Automated Guided Vehicles (AGV)

Looking to understand Automated Guided Vehicles in a little more detail?

We’ve compiled some helpful resources to get you started, covering everything you need to know.

Interested in discussing an AGV system for your operations?

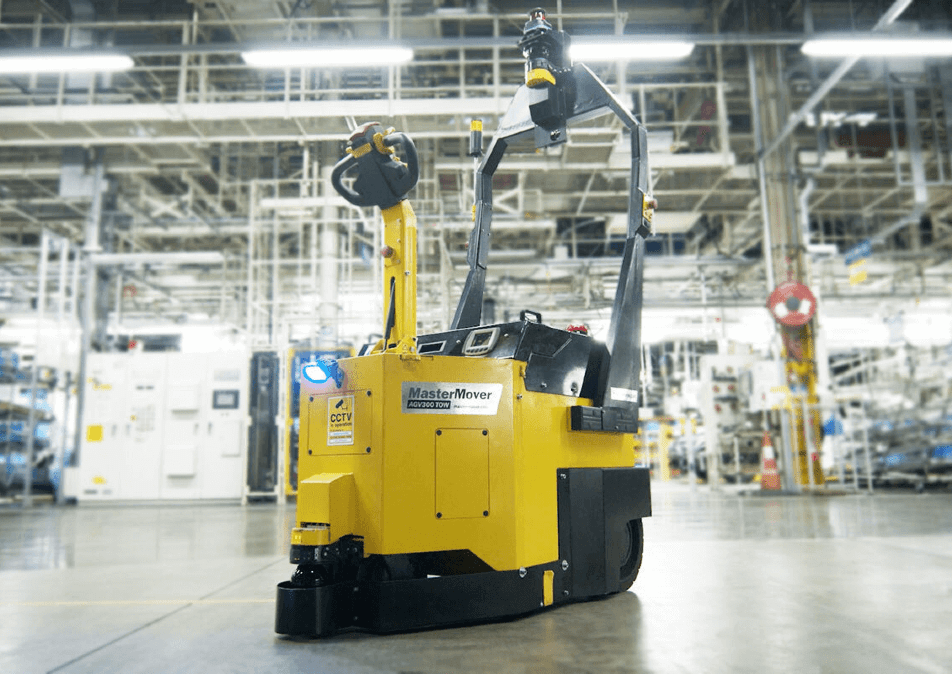

MasterMover offers a range of AGV solutions that can be tailored to your specific needs. If you’d like to learn more about AGVs and our unique automated towing offerings at MasterMover, download our guide today.

Automated Guided Vehicles

Maximize production efficiency and accuracy with an AGV

Our autonomous guided vehicles (AGVs) deliver the predefined, controlled movement of heavy loads – without the need for an operator.

You can maximize efficiency and guarantee the safe and precise movement of high-value loads every time with our AGV systems.

AGV electric tuggers in your operation

If you’d like to talk to us about benefitting from the power of autonomous electric tugger solutions in your business, we’d love to talk…

Our team possess a wealth of experience and we’d welcome the opportunity to understand your challenges, requirements and opportunities for AGV system within your business.