Load Moving Castors

Material handling electric tugs

Thank you for submitting your consultation request.

A member of the team will be in touch shortly.

They're more important than you think

If you drive a car, you know how important tyres are in getting you moving, allowing you to stop, and manoeuvre, all while keeping your vehicle in contact with the road. Castors on carts, dollies and trolleys in industrial settings are no different, they facilitate the fundamental method of movement – rolling.

While castor wheels aren’t the most exciting topic, their importance shouldn’t be overlooked. Taking a little time to understand castors could save you money, time and help reduce safety issues for staff.

For loads mounted on castors, they are the single point of the load in contact with the floor – making them a crucial part of your trolley. This means they play a large part in dictating how easy it is to start a load moving, manoeuvre or steer it, and bring it to a stop – all while supporting your load weight!

Castor wheels are a key factor to consider when it comes to how a load is moved, particularly when using material handling equipment like electric tugs.

Castor wheel types and materials

There are two predominant types of castor wheels:

Fixed castors

As the name suggests, they are fixed and facilitate a forward/backwards movement only.

Generally, loads with fixed castors are installed in combination with swivel castor wheels to allow manoeuvrability with handling aids like electric tugs or electric tow tugs.

Swivel castors

The castor rotates in a 360-degree motion, allowing steering and manoeuvrability. Swivel castors can be equipped with a directional lock, which turns them from a swivel castor to a fixed one using a simple locking mechanism – allowing you to move the load differently depending on the application.

Influencing factors

When using an electric tug, this allows you to position the tug to correspond with your castor set-up, allowing maximum manoeuvrability.

In industrial settings, the most common types of castor wheel materials include nylon, polyurethane, rubber, and steel.

Each castor material type has specific attributes which in turn, influence the rolling resistance of the castor. For example, steel castors running on rails have a very low rolling resistance which means less force is required to start the load moving and stop it.

Rolling resistance

There are several variables which can influence rolling resistance in addition to castor material, including:

- Castor condition

- Castor orientation

- Slopes

- Floor material and condition,

- Presence of debris

- Weather conditions

When it comes to material handling equipment, specifically electric tow tugs, reputable suppliers will use the information on your environment and castors to calculate the rolling resistance and in turn, the force required to move and slow down a load.

From this, they’ll then be able to specify a suitably equipped tug or tow to move your load. This may sound like a ‘dark art’, but a credible tow tug supplier will use basic physics to outline what your estimated rolling resistance is, the force needed to move the load and then the capabilities of the solution specified.

3 Common castor wheel configurations

Loads can come with a variety of weird and wonderful castor wheel configurations, but 3 of the most common set-ups seen in industrial settings are:

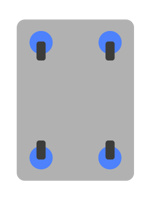

4 x fixed castors

This is used only for straight-line operations (often on rails or recessed tracks). With 4 x fixed wheels you cannot steer or turn the load.

4 x swivel castors

A set-up that is generally fitted to lighter equipment or where flexibility of movement is required. An all-swivel set up makes it tricky to steer and position a load with handling aids.

When moving an all-swivelling load with electric tugs, there are two options to provide the controlled movement – either a machine equipped with a fixed point or to utilise two machines.

This setup can also feature directional locks in which case it operates in the same way as a 2 x fixed, 2 x swivel set-up but with the added flexibility to change configurations as required.

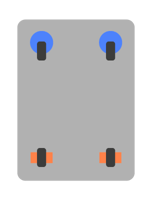

2 x fixed, 2 x swivel

The most common configuration across many industries, this setup facilitates easy-to-control movements – and is best suited for use with handling aids like electric tugs.

Of course, countless other configurations exist, ranging from a mixture of castors and support legs to swivel castor set-ups with central fixed castors.

The castor configuration you choose, or already have will influence the range of movement available to you so it’s important to consider this.

5 Things to keep in mind

Now you have an overview of the different styles and configurations of castors, here are a few things to keep in mind when looking to buy new castors, or assessing the suitability of your current castors:

Thank you for submitting your consultation request.

A member of the team will be in touch shortly.

-

1. Load Weight Capacity

Make sure any castors you select are rated to the weight you need to move (or even offer scope for future heavier requirements). Heavy loads will require different types of castor and may need twin wheel castors.

-

2. Castor Condition

Loads with worn or damaged castor wheels will increase rolling resistance and in turn require significantly more force to move, in some cases up to 20% more force!

If you’re looking into using a handling aid like an electric tow, this will increase the machine specification needed to cope with the high rolling resistance. (Tip: new castors help, a lot!)

-

3. Castor Quantity

The number of castors can also have an impact on rolling resistance. It’s important to speak with a reputable castor supplier to ensure that your load weight, specific point loading and application are considered when deciding on the number and position of castors.

-

4. Castor Material

Your floor will also influence which castor material you may select as you might need castors that are suitable for indoor and outdoor use.

Hard tread wheels tend to be better on soft or smooth floors, while softer tread wheels are preferable for rougher conditions.

-

5. Purchase Quality

As with anything, you get what you pay for, and the final point to keep in mind when buying castors is quality.

High-quality castors designed for industrial settings are a worthwhile investment in ensuring rolling resistance is kept as low as possible and guarantees the longevity of your equipment and flooring.

The ultimate guide to electric tugs

Electric tug essentials

Looking to understand electric tugs in a little more detail?

We’ve compiled some helpful resources to get you started, covering everything from how they work, different types of batteries, getting the right connection point and more…

-

What is an electric tug?

-

5 benefits of electric tugs

-

Price guide

-

Do you need a license?

-

How electric tugs work

-

Batteries & charging guide

-

Couplings & connections

-

Tugs vs tows

-

Frequently asked questions

-

Why businesses use electric tugs

-

Pedestrian operated vs remote control

-

Automation & remote control options

Safely move your wheeled loads

We have an extensive range of electric tugs and tow tugs specifically designed to improve the safety and efficiency of moving heavy-wheeled loads.

With these tips on castor specification and set-up, all you need now is an electric tug or electric tow to deliver powerful, safe movements of your wheeled equipment.

As experts in moving heavy-wheeled loads, we can advise you on castors, trolleys, tow tugs, and everything in between.

For applications where you’d like a trolley designing and manufacturing alongside our electric tugs – we can do that too, delivering a turnkey package that’s ready to work right out of the box.

We're here to help

If you’re looking to improve safety, remove the risk of injury and unlock greater operational efficiency, we’re here to help. Speak to our team to discuss your application.