Continue reading

Continue reading

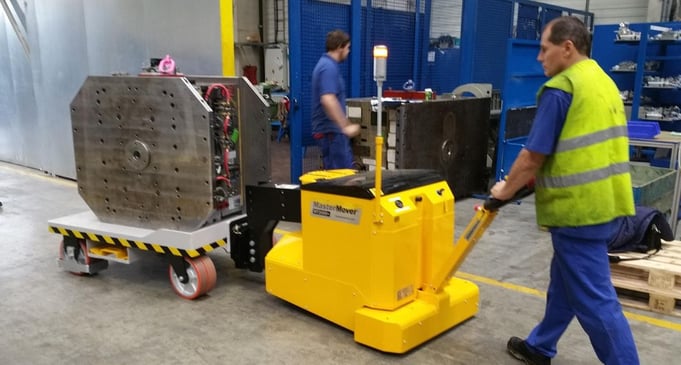

Automotive Vehicle Material Handling Equipment

Thank you for submitting your demo request.

A member of the team will be in touch shortly.

Thank you for submitting your consultation request.

A member of the team will be in touch shortly.

Typical electric tug applications

Automotive original equipment manufacturers (OEMs), tier 1 suppliers and commercial vehicle manufacturers use electric tow tugs to move a wide variety of tooling, components and equipment such as:

- Body panels, body-in-whites and chassis

- Transmissions, drive shafts & axles

- Powertrains & gearboxes

- Interiors, lighting & safety systems

- Kitting trolleys

- Injection mould & press tools

Benefits for automotive manufacturing

Create leaner processes

Streamline internal transportation with license-free electric tugs, cutting down on inefficiencies for leaner, faster workflows.

Unlock flexible production

Adapt to evolving production needs with the flexibility of electric tugs, enabling modular and scalable processes that fixed systems can't match.

Shift safety up a gear

Electric tugs eliminate manual handling, empowering staff to focus on high-value tasks while improving safety and reducing risk.

Drive efficiency

Reduce downtime and optimise material movement with electric tugs, accelerating efficiency and keeping production on track.

Our range of automotive electric tugs

Our automotive & commercial vehicle equipment in action

When is an electric tug is the right solution?

For automotive OEMs, Tier 1 suppliers and commercial vehicle manufacturers, creating lean and efficient processes is crucial. Our electric tugs and AGVs are a great fit when:

- Your existing intralogistics and material movement processes are slow and inefficient

- Bottlenecks occur from waiting for licensed forklift truck drivers

- Tow tractor routes are highly repetitive

- You’re looking to eliminate manual handling

AGV Systems – Case Study

Toyota accelerates efficiency with an AGV system

A world leader in its field, the automotive manufacturer has achieved return on investment and improved operational efficiency when moving parts to the production line with our Automated Guided Vehicle (AGV) solutions.

Trusted by global automotive and commercial vehicle OEMs

With an expansive customer base made up of the world’s leading automotive manufacturers, you’re in safe hands.

I’d certainly be happy to recommend the MasterMover AGV to other organisations looking to automate their driving processes.

Kevin JonesPrincipal Engineer Assembly Engineering, Toyota Motor Corporation

Why choose MasterMover?

- The world's leading manufacturer of electric tugs for over 25 years

- Over 40+ electric tugs to choose from

- Trusted by the world’s leading automotive manufacturers, tier suppliers, and tyre manufacturers

- In-house custom engineering capabilities

- Winner of the King's Award for Innovation 2023 & Queen's Award for International Trade 2021

- Global sales and support

We're here to help

If you’re looking to improve safety, remove the risk of injury and unlock greater operational efficiency, we’re here to help. Speak to our team to discuss your application.

Your Questions, Answered - FAQs

- Pedestrian operated electric tugs allow a single operator to safely manoeuvre even the heaviest loads with confidence, removing manual handling and reliance on forklift trucks.

- Remote control operation is available to deliver maximum visibility by allowing operators to take up the ideal vantage point when moving loads, facilitating the seamless movement of loads in congested areas.

- Automated AGV electric tugs remove the need for an operator, automating the movement of heavy loads to maximise efficiency and resource utilisation.

Electric tugs are available with multiple control options designed to suit the needs of modern automotive manufacturing:

No, unlike lifting equipment such as forklift trucks and cranes, an electric tug does not require a license to operate. A license-free operation reduces downtime and maximises operational efficiency, reducing wasted time waiting for a licensed driver.

Minimal training is required to safely operate an electric tug and we offer training packages to suit every requirement.

Electric tugs are battery powered, with interchangeable batteries or lithium options available, electric tugs can deliver 24/7 operation to keep your processes moving.

Offering zero emissions from the point of use, electric tugs are ideally suited for indoor use, replacing internal combustion engine (ICE) powered equipment such as forklifts or tow tractors.

A range of coupling options are available across the range that maximise performance, security and safety. Custom coupling solutions can also be designed for unique applications.

Interested in learning more? Read the latest articles

Continue reading

Continue reading

Six New Models Expand the PowerSteered Range for Fingertip Control