Forklift Options: Choosing The Best For Your Business

Material handling equipment

Thank you for submitting your consultation request.

A member of the team will be in touch shortly.

At MasterMover, we're committed to facilitating seamless business operations by guiding you towards the best material handling solutions. While our expertise lies in offering top-notch electric tug solutions to move heavy loads, we understand the pivotal role forklift trucks play in various sectors and applications.

In this review, we've thoroughly examined some of the top forklift truck brands to provide you with the answers you need and guide you in making an educated choice for your business.

What to Consider When Choosing a Forklift Truck?

Like any equipment, assessing which forklift truck is right for your application involves assessing several areas.

Product Utilisation

The first factor to consider is how much you are going to use a forklift. For example, if you will have high utilisation across multiple shifts and where drivers will be using the forklift truck throughout the day, you may want to consider a truck that includes ergonomic features such as more comfortable seating and controls.

Total Cost of Ownership

With 95% of all forklift trucks hired instead of purchased, understanding the total cost of ownership for your lift truck is crucial. This consideration involves assessing finance costs, maintenance options, quality of construction and overall running costs.

Safety Features

Buyers of forklift trucks should prioritise safety by considering factors like stability, cab visibility, safety enclosures, braking systems, warning systems, speed control, restraints and emergency stop systems. Choosing the right forklift type and attachments is also a crucial consideration when it comes to safety.

Speed

When purchasing a forklift truck, consider any restrictions on equipment speed on your site. Forklift trucks have a maximum speed of 18kph but in practice, many companies install limiters to ensure that operators do not exceed site or area speed limits, despite the forklifts having the capacity for higher speeds.

Lifting Capacity

The capacity of a forklift truck is a critical consideration because it directly impacts safety and utilisation. You should ensure you assess the lifting capabilities at various heights to ensure the forklift meets your business demands.

Power Type

Depending on your preference and operational requirements, it’s important to assess how your forklift truck will be powered i.e., diesel, electric or LPG. Selecting the appropriate power type for a forklift truck is a crucial decision with significant operational implications. The choice should align with operational needs, considering tasks, indoor or outdoor usage, run-time requirements, emissions regulations and objectives, and available infrastructure.

Electric forklifts are environmentally friendly and quiet but have limited run times (though this can be addressed with effective charging and/or lithium options). Diesel forklifts offer high power and durability but emit emissions and are noisy. LPG forklifts provide versatility and longer run times, but require space for fuel storage.

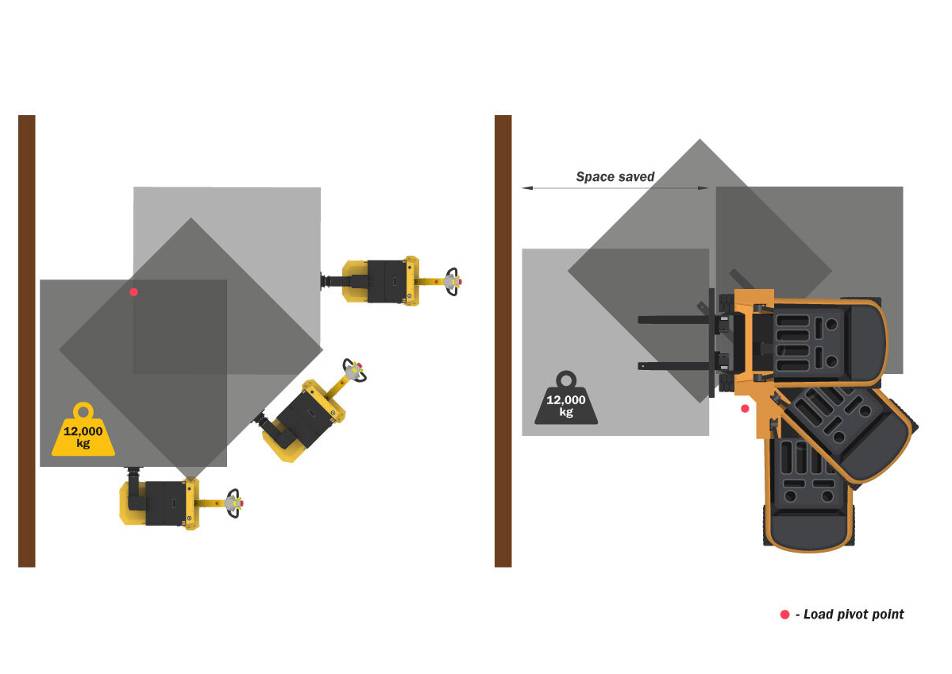

Size & Machine Footprint

In almost every industry, space is at a premium. Considering space is crucial when choosing a forklift model to ensure they are well-suited to the operating environment. Smaller forklifts with tight turning circles are advantageous in confined spaces, promoting efficient material handling and overall safety.

Type of Forklift

Like any equipment, there are a range of different types of forklifts on the market. Understanding the variety of products a brand offers can help you find a solution tailored to your needs. Common types of forklifts include counterbalance trucks, reach trucks, order pickers and rough terrain forklifts.

When are Forklift Trucks Not the Right Solution?

While forklift trucks are a staple in many warehousing and manufacturing environments, they are not always the best solution - particularly where loads are on wheels and castors.

In bustling manufacturing settings where there is significant movement, relying on forklifts can increase the risk of accidents, particularly in congested pedestrianised areas.

Electric tugs and tows emerge as a more prudent choice in this environment. Here’s why:

Safety First

Electric tugs are designed to prioritise safety, especially in environments with a high density of workers. Their operational design minimises the risk of accidents, which can be a common concern with forklifts traversing through busy areas.

A key concern for many businesses when it comes to the safety of equipment is speed. Ride-on or driven equipment can travel at higher speeds than pedestrian equipment, with forklift trucks reaching a maximum of 18kph. However, the safety of large trucks moving through facilities and yards at speed is questionable, with many businesses limiting the speed of equipment to meet site legislation. Where loads need to be moved in busy, congested environments, an alternative solution – like electric tugs may be a safer option.

Versatility in Applications

Electric tugs are known for their versatility, capable of handling a wide array of tasks and the ability to move multiple loads at once. This makes them a more flexible choice in manufacturing settings, where the nature of tasks can vary greatly. Likewise, electric tugs offer the capability to move loads of up to 70,000kg with a single machine without compromising the safety or efficiency of an operation.

No Operator License Required

One of the standout advantages of electric tugs is the fact that they don't require an operator's license. This means that they can be operated by a broader range of personnel without the need for specialist training that is typically required for forklift operation. This not only saves time but also enhances operational efficiency.

Efficiency in Operations

Electric tugs are synonymous with efficiency. They are engineered to streamline the process of moving products, equipment, and materials within manufacturing environments. The ability to be operated by any individual means tasks can be completed more swiftly, avoiding the delays that might occur as teams wait for a licensed forklift driver to become available.

Introducing a Safer Alternative in Pedestrianised Areas

Using forklifts in areas with high pedestrian traffic is risky and can hamper the smooth flow of operations. On the other hand, electric tugs can seamlessly integrate into these environments, ensuring safety while not compromising efficiency.

In light of these factors, it becomes clear that electric tugs can offer a more suitable, safe, and efficient alternative for material handling in various settings, supplementing the roles traditionally held by forklift trucks.

At MasterMover, we specialise in providing high-quality electric tug solutions that meet the diverse needs of modern manufacturing environments, fostering a culture of safety and efficiency.

What are some of the benefits of electric tugs?

-

1. License-free operation

One major benefit of electric tow tugs is that they do not require specialist licenses to operate. This is because, unlike forklifts, electric tow tugs don’t lift loads, so they do not fall under LOLER regulations (Lifting Operations ad Lifting Equipment Regulations, 1998).

-

2. Reduced downtime

This makes electric tow tugs an ideal solution for intense production environments. Their license-free operation means any member of staff can easily execute controlled movements, removing the need to wait around for a licensed driver, and significantly reducing downtime. This makes them perfectly suited for delivering parts to the production line or transferring heavy loads through assembly stages.

-

3. Improved workplace safety

Removing the lifting operation, electric tugs mean loads stay safely on the ground, enabling you to improve safety. Many organisations are opting for electric tugs to create fork-free operations, enabling them to remove the risk of collisions with pedestrians and reduce injuries.

With intuitive, ergonomic controls, electric tugs require zero physical exertion from operators, empowering staff to move loads of up to 360,000kg with ease and achieving a secondary benefit in reducing manual handling.

-

4. Reduced maintenance costs

Compared to forklift trucks, the electric tug design reduces maintenance costs. With an easy-to-service construction, they deliver the most cost-effective solution that will deliver time and time again.

-

5. Increased flexibility

With a modular design, electric tugs enable you to benefit from maximum flexibility. As a versatile solution, tow tugs can be utilised on multiple applications or move long trains of loads to further increase productivity.

Comparison: The Top Forklift Truck Brands

In this section, we scrutinise forklift manufacturers based on the factors mentioned above, providing a detailed insight into their offerings:

-

Toyota Material Handling

-

Linde Material Handling

-

Hyster-Yale Materials Handling

-

Jungheinrich

-

Crown Equipment Corporation

-

Mitsubishi Logisnext

-

Doosan Industrial Vehicle

-

Cesab

-

EP Equipment

Toyota Material Handling

Range of Forklift Products

Toyota Material Handling offers a broad range of forklift products catering to various needs and applications. Their line-up includes counterbalance trucks, warehouse equipment, and towing tractors. Whether you're looking for reach trucks or pallet trucks, Toyota has a diverse range to meet different operational demands and is well-known in the material handling industry.

Power Type

Toyota provides both electric and ICE engine-powered trucks. Their electric models are known for their eco-friendliness and low noise levels, while the engine-powered trucks excel in terms of power and reliability.

Load Capacity & Lifting Capacity at Height

Toyota’s forklift trucks come with different load capacities to suit various operational requirements. From high-capacity ICE trucks capable of handling up to 8 tons to smaller electric trucks ideal for navigating narrow aisles, they offer a range of options. Moreover, their reach trucks can manage heights of up to 13 meters, ensuring efficient high-level stacking.

Additional Comparing Factors

Toyota stands out with its commitment to innovation and sustainability. Their I_Site fleet management system integrates smart technology into their trucks, enhancing safety and efficiency. Furthermore, they offer comprehensive after-sales support, ensuring smooth operation throughout the product's life cycle.

Linde Material Handling

.png?width=204&height=122&name=download%20(7).png)

Range of Forklift Products

Linde Material Handling offers a comprehensive range of forklift trucks designed to cater to diverse industry needs. From electric forklifts to diesel and gas-powered trucks, they have solutions that cater to both indoor and outdoor operations. Their range includes counterbalanced trucks, reach trucks, and even autonomous trucks.

Power Type

Linde offers electric, diesel, and gas-powered forklift trucks. Their electric range is popular for its efficiency and environmental friendliness, while the IC trucks are preferred for heavy-duty tasks requiring higher power output.

Load Capacity & Lifting Capacity at Height

Linde’s forklifts are built to handle a variety of load capacities, catering to different operational demands. Their electric counterbalance trucks can handle loads between 1.4 to 5 tons, while the ICE trucks can handle up to 8 tons. Linde's reach trucks also boast excellent lift heights, capable of reaching up to 13 meters, thus offering optimised storage and retrieval solutions at great heights.

Additional Comparing Factors

Linde distinguishes itself with its focus on ergonomic design and safety. Their trucks are designed with operator comfort in mind, featuring spacious cabs and intuitive controls. Furthermore, Linde offers a range of automation solutions, integrating the latest technology to facilitate smart and efficient operations.

Hyster-Yale Materials Handling

.png?width=173&height=173&name=download%20(8).png)

Range of Forklift Products

Hyster-Yale offers a robust range of material handling equipment, including a diverse range of high-capacity, heavy duty forklift trucks. Their product spectrum encompasses large-capacity trucks, warehouse trucks, and container handlers, all designed to tackle different kinds of operational challenges with efficiency.

Power Type

Hyster-Yale presents a mix of electric and internal combustion (ICE) forklifts. Their electric series are characterised by zero emissions and quiet operations, making them suitable for indoor applications. Meanwhile, their IC trucks, powered by diesel or LPG, are typically deployed for more heavy-duty tasks, especially in outdoor settings.

Load Capacity & Lifting Capacity at Height

The brand offers a varied range of load capacities, ensuring you find a product tailored to your operational requirements. Their electric forklifts can handle loads ranging from 1.5 to 3.5 tons, whereas the diesel-powered ones can manage up to an impressive 16 tons, catering to heavy-duty industrial operations.

Additional Comparing Factors

Hyster-Yale is renowned for its innovative designs and technological integrations. They offer telematics and fleet management solutions to enhance their trucks' operational efficiency and safety.

Jungheinrich

![]()

Range of Forklift Products

Jungheinrich offers an extensive range of forklift trucks to suit various operations and applications. Their product portfolio includes electric counterbalance trucks, reach trucks, and pallet trucks, all designed to optimise warehouse and logistical operations.

Power Type

Jungheinrich primarily focuses on electric forklift trucks, offering a range that combines efficiency with emission-free operations. Their electric series stands out for its low maintenance design and operational cost-effectiveness, providing a sustainable alternative for material handling tasks.

Load Capacity & Lifting Capacity at Height

The brand provides forklifts with varying load capacities, catering to a diverse set of operational demands. Their electric counterbalance trucks can manage weights between 1.6 to 5 tons, making them a viable choice for a range of applications. Moreover, their reach trucks are capable of achieving impressive lift heights, facilitating effective high-level stacking and retrieval.

Additional Comparing Factors

Jungheinrich is recognised for its innovative approach, offering a range of warehouse solutions, including automated systems and comprehensive fleet management software. Their focus on ergonomics and safety ensures that operators can work with improved efficiency and safety.

Crown Equipment Corporation

Range of Forklift Products

Crown Equipment offers a comprehensive line-up of material handling solutions, including a diverse range of forklift trucks. Their offerings include counterbalance forklifts, pallet trucks, and stackers, all designed to provide reliable solutions for various industrial requirements.

Power Type

Crown Equipment primarily offers electric-powered forklift trucks. Their electric series is known for delivering exceptional power and efficiency, coupled with reduced emissions, making them a sustainable choice for modern businesses.

Load Capacity & Lifting Capacity at Height

Crown’s forklifts come in different capacities to suit specific industrial needs. Their range includes trucks capable of handling loads from small pallets to heavy-duty materials. Additionally, their reach trucks are designed to offer significant lift heights, ensuring smooth operations even in high-stacking environments.

Additional Comparing Factors

Crown sets itself apart with its focus on operator comfort and safety. Their forklifts feature intuitive controls and well-designed cabs, aiming to reduce operator fatigue and enhance productivity. Crown also offers a range of fleet management and service solutions, ensuring the long-term reliability and efficiency of their trucks.

Mitsubishi Logisnext

![]()

Range of Forklift Products

Mitsubishi Logisnext offers an impressive line-up of material handling solutions, including counterbalance forklifts, pallet trucks, and stackers, designed to provide reliable solutions for various industrial requirements.

Power Type

Mitsubishi provides an array of different forklifts and power types, covering internal combustion engines, electric and LPG, with their diesel forklifts able to lift up to 10,000kg.

Load Capacity & Lifting Capacity at Height

Mitsubishi forklift trucks come in different capacities to suit specific industrial needs, with reach trucks designed to offer significant lift heights, ensuring smooth operations even in high-stacking environments.

Additional Comparing Factors

Mitsubishi consists of multiple other well-known forklift brands, including UniCarriers, Mitsubishi Caterpillar, Nichiyu, Rocla and TCM. With a well-established heritage in industrial equipment, Mitsubishi is known for their wide product portfolio and innovation.

Doosan Industrial Vehicle

Range of Forklift Products

Doosan Industrial Vehicle is known for its diverse range of material handling solutions, including forklift trucks like counterbalance forklifts, pallet trucks, and stackers, providing versatile solutions for industrial needs.

Power Type

Doosan primarily offers reliable and cost-effective material handling solutions, which include a range of power options, including electric and internal combustion forklifts.

Load Capacity & Lifting Capacity at Height

Doosan provides a range of load capacities to accommodate specific industrial demands and offers solutions for varied stacking heights. Their 9-Series diesel trucks can lift loads of up to 16,000kg.

Additional Comparing Factors

Doosan Industrial Vehicle focuses on reliability, efficiency and keeping their customers’ machines up and running. Doosan states that they can supply local dealers with spare parts within 1-2 days to maximise forklift truck uptime.

Cesab

Range of Forklift Products

Cesab is a prominent manufacturer of material handling equipment, offering a comprehensive range of forklift trucks and solutions. Their product lineup includes a variety of forklift types, such as counterbalance forklifts, reach trucks, pallet trucks, and order pickers, catering to diverse industrial requirements.

Power Type

Cesab primarily provides electric-powered forklift trucks, emphasising efficiency, eco-friendliness, and reduced emissions. They also offer a range of other power options, including LPG and diesel, to suit specific industrial needs.

Load Capacity & Lifting Capacity at Height

Cesab's forklifts are available in various load capacities, ensuring they can handle a wide range of materials and loads. They also offer reach trucks designed to achieve significant lift heights, enabling efficient operations in high-stacking environments.

Additional Comparing Factors

Cesab offers a range of electric forklifts, with much of its core business focused on warehouse operations. Cesab also offers a range of fleet management and service solutions to ensure the ongoing reliability and efficiency of their forklifts, making them a comprehensive choice for businesses seeking dependable and user-friendly material handling equipment.

EP Equipment

Range of Forklift Products

EP Equipment is a leading manufacturer of material handling equipment, offering a wide range of forklift trucks and solutions. Their product portfolio includes various forklift types, such as electric counterbalance forklifts, reach trucks, hand pallet trucks, stackers, and order pickers, providing comprehensive solutions for diverse industrial applications.

Power Type

EP Equipment specialises in cost-effective, smaller electric-powered forklift trucks, known for their efficiency and eco-friendly operation. Their electric forklift series is designed to deliver reliable performance while minimising emissions and reducing the environmental impact, making them a sustainable choice for modern businesses.

Load Capacity & Lifting Capacity at Height

EP Equipment's forklifts are available in different load capacities, ensuring they can efficiently handle a wide range of materials and loads. The majority of their models are electrically powered, though three diesel options exist, providing up to 10,000kg capacity and maximum lifting heights of 6000mm.

Additional Comparing Factors

EP Equipment places a strong emphasis on operator comfort and safety at affordable prices. Their forklifts feature ergonomic controls and well-designed cabins to reduce operator fatigue and enhance productivity.

The ultimate guide to material handling

Material handling equipment

Looking to understand material handling in a little more detail?

We’ve compiled some helpful resources to get you started.

-

10 Principles of MHE

-

Advanced MHE

-

Material handling in manufacturing

-

Forklift trucks vs electric tugs

-

Shunters vs electric tugs

-

Tow tractors vs electric tugs

-

Overhead cranes vs electric tugs

-

AGVs vs Traditional MHE

-

A fork-free future

-

What is intralogistics?

-

Diesel forklift alternatives

-

Benefits of tugger trains

Applying a Forklift Truck Comparison

Choosing the right material handling equipment is pivotal in optimising operational efficiency, ensuring safety, and meeting the varied demands of modern manufacturing and warehousing environments.

As we've seen, brands like Toyota, Linde, Hyster-Yale, Jungheinrich, and Crown each offer unique sets of advantages, ranging from innovative technology integrations to versatile product ranges.

While forklift trucks stand as a reliable option for lifting and moving materials over short distances, they are not always the perfect solution, especially in high-traffic, pedestrianised areas. In such scenarios, electric tugs and tows from MasterMover present a safer and more versatile alternative, proving to be a vital asset in enhancing operational efficiency.

As you navigate the decision-making process, remember to consider your operation's specific demands and each brand's unique offerings.

Frequently Asked Questions (FAQs)

When choosing a forklift brand, consider factors such as the range of products offered, power type (electric or diesel), load capacity and capacity at height, and any additional features or offerings that might suit your operational needs.

Electric forklifts are known for low noise operation, lower emissions, and often have lower operating costs over time. In contrast, diesel-powered forklifts offer higher power output, making them suitable for heavy-duty tasks, particularly outdoors.

One of the advantages of electric tugs is that they do not require a specialist operator license, allowing a broader range of personnel to operate them, thereby enhancing efficiency in material handling tasks.

Electric tugs are designed to integrate seamlessly into high-traffic pedestrianised areas, offering a safer and more efficient alternative to forklift trucks, which can pose safety risks and disrupt the smooth flow of operations in such environments.

At MasterMover, we specialise in providing high-quality electric tug solutions tailored to meet the diverse needs of modern manufacturing environments.

Our offerings focus on fostering a culture of safety and operational efficiency.

We're here to help

If you’re looking to improve safety, remove the risk of injury and unlock greater operational efficiency, we’re here to help. Speak to our team to discuss your application.