The Benefits of Tugger Trains

Material Handling Equipment

Industries from manufacturing to logistics continuously strive for more efficient processes. As part of this, many businesses look to assess their internal logistics processes to identify areas of improvement and opportunities to streamline processes and improve flexibility.

Thank you for submitting your consultation request.

A member of the team will be in touch shortly.

Tugger Train Systems for Material Handling

Fuelled by rapid innovation in material handling equipment, tugger train systems are increasingly used by businesses to maximise efficiency in internal logistics.

In this blog, we’ll explore what tugger trains are, and how they continue to revolutionise the way factories and distribution centres handle materials and manage their internal transportation, leading to enhanced productivity, reduced costs, and more efficient operations.

What are Tugger Trains?

Tugger trains, often referred to as tugger carts, are a modern solution for material handling within factories and warehouses. At their core, they involve the use of a powered vehicle such as an electric tug (the tugger) or tow tractor pulling a series of carts or trailers on castors, which are loaded with materials, components, or products.

Offering a more mobile alternative to pallets, they deliver greater flexibility and enable the safe, efficient movement of heavy loads in production supply and warehouse operations.

How do Tugger Train Systems Work?

Tugger trains pick up materials and products at designated locations around the facility. An operator loads components onto the load carriers or trolleys and then drops them off at appropriate drop-off points along the tugger train’s designated route. Multiple load carriers allow for the transport of a greater number of loads in one trip around the facility.

The Benefits of Tugger Trains

Tugger train systems offer a range of benefits over traditional material handling methods and systems. They efficiently move heavy loads, reduce manual labour, and improve material flow – becoming increasingly popular with companies looking to streamline their operations and increase productivity.

A tugger train system also naturally reduces internal traffic by moving multiple loads at once. Combining tugger train systems with lean principles and milk-run logistics enables businesses to implement a cyclical work process, ensuring internal transport runs smoothly.

Thank you for submitting your consultation request.

A member of the team will be in touch shortly.

-

Increased Efficiency

Tugger trains enable batch transportation of materials, allowing operators to move multiple loads at once. This approach is far more efficient than shuttling individual items back and forth. With a tugger train system, businesses can reduce travel time, the number of trips required and increase the number of materials moved per trip.

-

Maximise staff productivity and safety

Using electric tugs empowers highly skilled staff to focus on tasks of greater value add, improving productivity and eliminating manual handling.

-

Unlock greater flexibility

Tugger trains can handle a wide range of loads, making them ideal for handling different types of materials such as components, work-in-progress, or finished products.

-

Improved Safety

Tugger train systems often come with advanced safety features, including collision avoidance technology and ergonomic design, reducing the risk of accidents and injuries in the workplace, particularly where loads were previously moved using forklifts or through manual handling.

-

Reduced Costs

Tugger trains can replace multiple forklifts or other manual transportation methods, leading to reduced labour costs and lower maintenance expenses.

-

Space Optimisation

Tugger trains can manoeuvre through tight spaces more effectively than traditional vehicles like forklifts, optimising floor space within factories and warehouses.

Intralogistics Solutions to Replace Forklift Trucks and Manual Handling

Tugger train systems have replaced traditional forklifts and other manual transportation methods in many facilities due to their numerous benefits. For many organisations, components were moved using a forklift truck or manually by staff, presenting efficiency and safety challenges.

With the clarion call for businesses to improve operational efficiency, the downtime associated with waiting for a licensed forklift driver is an inefficiency many businesses are looking to address. Alongside this, using forklift trucks to facilitate the movement of loads inside congested environments presents a number of safety hazards.

The challenges of safely manoeuvring large forklifts in tight areas and around pedestrians has led many businesses to pursue fork-free operations – an approach that utilises electric tugs to create tugger trains and eliminates the use of forklift trucks on the shop floor.

What About the Milk Run Logistics Concept?

‘Milk run logistics’ is a concept derived from the way milk is collected from various suppliers using a single route. Applied to manufacturing, it involves optimising the flow of materials and components from station to station within a facility, reducing waste and improving efficiency.

Tugger trains play a pivotal role in implementing milk run logistics, facilitating multiple drop-offs of components or parts along the route.

Utilising Tugger Trains in Milk Run Logistics

Regular Routes: Tugger trains follow predefined routes, collecting materials from various points and stations within the production process. This systematic approach minimises the need for excess movement and reduces congestion.

Just-in-Time Supply: By adhering to a scheduled route, tugger trains deliver materials to production lines just-in-time, preventing overstocking and minimising storage requirements.

Synchronisation: Tugger train systems typically work in tandem with production schedules, ensuring that materials are delivered exactly when they are needed. This synchronisation reduces downtime and keeps the production line running smoothly.

Lean Principles: The use of tugger trains, forklift-free processes and milk run logistics align with lean manufacturing principles by eliminating waste, optimising processes, and maintaining a continuous flow of materials.

Different Types of Tugger Train Systems and Carts

As part of a tugger train system, there are wide variety of different types of tugger cart configurations and towing vehicle available. Here, we walk you through some of the most common types to help you understand which tugger train solution is right for your application.

Tugger Train Trailers & Carts

-

Basic Tugger Cart & Load Carrier

-

Mother-Daughter Tugger Systems

-

Convertible Tugger Carts

-

Flatbed Trolley Cart

-

Shelf Tugger Carts

-

Roller Carts

-

Custom Tugger Carts

Basic Tugger Cart & Load Carrier

These are the fundamental tugger train systems consisting of a powered tugger vehicle pulling multiple carts or trailers. As the simplest form of tugger cart, they often use pre-existing carts or trolleys within a facility and simply use an electric tug or electric tow tractor to create a tugger train.

Mother-Daughter Tugger Systems

In this configuration, a larger "mother" cart is pulled by the tugger vehicle (either an electric tug or ride-on tow tractor), and smaller "daughter" carts are nested within the mother cart. This setup allows for the efficient transportation of multiple loads in one trip.

Daughter carts can be easily loaded and unloaded from the mother cart, making it a suitable goods carrier for facilities with diverse batch sizes and different types of components.

Convertible Tugger Carts

Convertible tugger carts and trolleys are designed to adapt to different types of materials or products. These carts often feature adjustable shelving, racks, or dividers that can be reconfigured to accommodate various load shapes and sizes. This flexibility is beneficial for facilities that handle a wide range of products, as the same cart can be repurposed for different tasks.

Flatbed Trolley Cart

Flatbed carts have a simple flat surface without walls, edges or compartments. They are ideal for transporting large or irregularly shaped items that may not fit in standard carts. Flatbed carts provide open space for easy loading and unloading, making them suitable for industries dealing with larger loads, such as automotive or heavy plant manufacturing.

Shelf Tugger Carts

Shelf carts feature multiple shelves or levels, making them suitable for transporting smaller items that need to be organised. These carts are commonly used in assembly lines or picking operations, where easy access to materials is essential.

Roller Carts

Roller conveyor carts use a system of rollers to facilitate the smooth movement of items, allowing for efficient transportation and easy picking of parts and components.

Custom Tugger Carts

Many manufacturers offer the option to create customised tugger carts tailored to specific transport requirements. This includes incorporating specialised compartments, fixtures, or attachments to accommodate unique materials or processes.

Each type of tugger train system and cart serves a particular purpose within material handling processes. The choice depends on factors like load size, shape, weight, material type, and the layout of the facility. By selecting the appropriate tugger train and cart configurations, businesses can optimise their internal logistics, enhance productivity, and ensure a seamless material flow.

Types of Tugger and Towing Equipment

Electric Tugs

Electric tugs, sometimes known as battery-powered tugs and electric tow tugs, are compact machines specifically designed to move heavy-wheeled loads within industrial manufacturing and logistics environments. With a scalable design and powerful load capacity, they are often used to create tugger trains and move multiple carts at once.

Electric tugs are a crucial type of material handling equipment relied on by businesses to reduce manual handling and forklift use in tight areas. Trusted to deliver the safe movement of trailer trains, electric tugs are used by manufacturing companies to support:

- A more efficient logistics process

- Just-in-time delivery of parts throughout a production facility

- Flexible operations

Available as pedestrian operated, remote control or as autonomous solutions (AGVs), electric tugs are compact – guaranteeing maximum manoeuvrability and safe movement in congested areas. With no operator license required, they boost operational efficiency and staff productivity.

Unlock more efficient operations

Ready to supercharge your operational efficiency and workplace safety with electric tugs?

Thank you for submitting your consultation request.

A member of the team will be in touch shortly.

Electric Tow Tractors

Available as ride-on towing tractors and stand-on designs, electric tow tractors are synonymous with warehouse environments. With a driver operating the vehicle, tow tractors are best suited to pulling trains of carts over longer distances.

Autonomous Tugger Train Systems

Automated Guided Carts (AGCs)

Automated guided carts (AGCs) are tugger carts equipped with technology, such as sensors, cameras, and navigation systems enabling them to work autonomously. They typically follow pre-defined paths (also known as line follow navigation) to navigate within a facility without human intervention. AGCs enhance efficiency by minimising manual guidance and can be integrated into complex material handling systems.

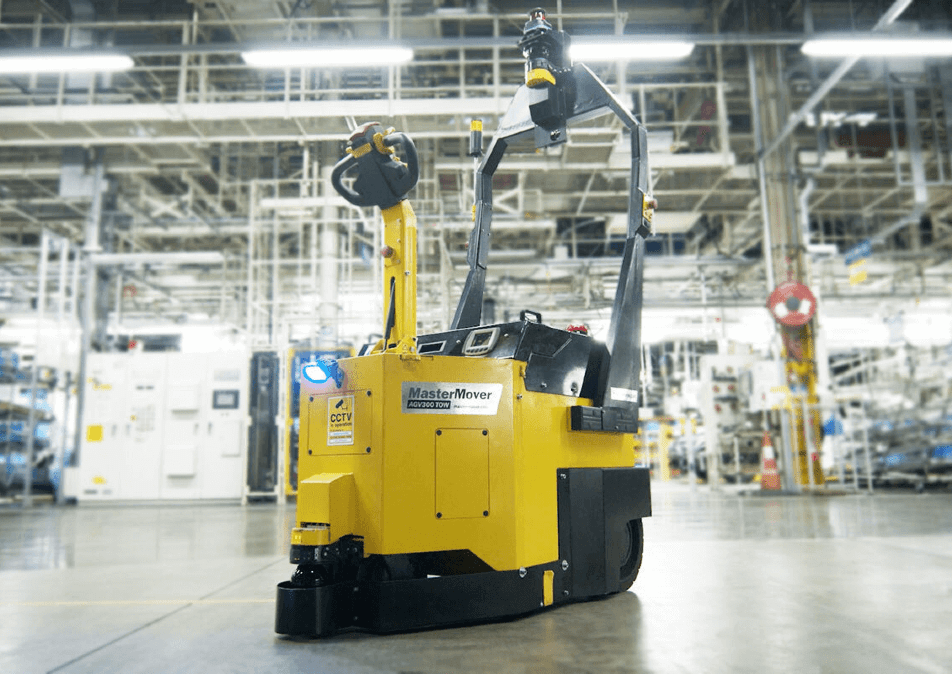

Automated Guided Vehicles (AGVs)

An automated guided vehicle (AGV) is a material handling system that travels autonomously without the need for an operator. With AGVs delivering significant efficiency gains, manufacturers across a range of industries are increasingly adopting the technology to mobilise their operations.

AGVs are available with line follow navigation (following a pre-defined path on the floor) or using natural navigation. The most sophisticated form of AGV, natural navigation machines use sensors and scanning systems to navigate autonomously by detecting and mapping the environment around them to move around obstacles.

AGV Systems – Case Study

Toyota accelerates efficiency with an AGV tugger train

A world leader in its field, the automotive manufacturer has achieved return on investment and improved operational efficiency when moving tugger trains of parts to the production line…

The ultimate guide to material handling

Material handling equipment

Looking to understand material handling in a little more detail?

We’ve compiled some helpful resources to get you started.

-

10 Principles of MHE

-

Advanced MHE

-

Best forklift trucks

-

Material handling in manufacturing

-

Forklift trucks vs electric tugs

-

Shunters vs electric tugs

-

Tow tractors vs electric tugs

-

Overhead cranes vs electric tugs

-

AGVs vs Traditional MHE

-

A fork-free future

-

What is intralogistics?

-

Diesel forklift alternatives

Your Questions, Answered - FAQs

- Pedestrian operated electric tugs allow a single operator to safely manoeuvre even the heaviest loads with confidence, removing manual handling and reliance on forklift trucks.

- Automated AGV electric tugs remove the need for an operator, automating the movement of tugger trains to maximise efficiency and resource utilisation.

- Remote control operation is available to deliver maximum visibility by allowing operators to take up the ideal vantage point when moving loads, facilitating the seamless movement of loads in congested areas.

A tugger train is a system used in material handling that consists of a powered tugger vehicle pulling multiple carts or trailers. The tugger vehicle moves materials within a facility, such as a warehouse or manufacturing plant, while the carts carry the goods. It's an efficient way to transport materials in a production or distribution environment.

Electric tugs offer several benefits, including lower operational costs, reduced emissions, quieter operation, and improved manoeuvrability. They are also more compact than traditional towing tractors or forklift trucks.

Electric tugs are available with multiple control options, including:

Yes, electric tugs are designed to handle a wide range of loads, including heavy materials. Their load-moving capacity depends on the specific model and design, but our electric tugs can move loads right up to 70,000kg - so more than enough capacity for towing tugger trains!

Electric tugs reduce the carbon footprint of material handling operations by eliminating the emissions associated with traditional handling equipment. They also offer improved energy efficiency and reduced noise pollution. This makes them a more sustainable and cost-effective option for businesses looking to streamline their material handling processes and intralogistics.

In its most basic form, you need some form of train system and a towing (or tugging) vehicle.

You need to make sure that the trolleys or carts you choose meet your operational requirements in terms of the products, parts and components they'll hold and how they link together to create a train system.

When looking at a towing or tugging solution, you want to assess equipment against 3 main criteria:

- Weight moving capacity and performance

- Size and profile

- Safety

We offer a wide range of electric tugs and towing solutions, ideal for implementing safe and efficient tugger train systems.

Discover More Efficient Intralogistics with Electric Tugs

Driving efficient processes, improved safety and greater flexibility, tugger trains have revolutionised intralogistics and material handling. Are you looking to streamline your material handling?

Contact us to discuss how electric tugs can help!