Key Takeaways from MODEX 2024

Atlanta, Georgia, was the epicenter of innovation as the Material Handling Institute (MHI) hosted MODEX 2024, North America's largest material handling and supply chain trade show. It was the largest MODEX show yet, with over 45,000 manufacturing and supply chain professionals attending and engaging with more than 1,000 exhibitors.

Amidst the record turnout, the MasterMover Inc team was showcasing our trusted range of electric tuggers, tows, and AGVs. We spent 4 days discussing everything to do with safer, more efficient material handling and how electric tuggers and AGV systems can help businesses across a diverse range of industries.

Alongside the show, MHI launched its 11th annual Industry Report, focusing on the transformative impact of collaborative and tech-driven supply chains. With insights from 1,675 respondents, the report emphasized the pivotal role of human-centricity in leveraging technological innovations effectively.

In this blog, we’ll dive into some of the key findings of the report and outline our top 3 takeaways from the show.

#1 The Time for Automation is Now

Every year MODEX and other industry trade shows showcase an array of innovative automation technology and robotics, but this year stood out with notable increases in automation and AGV offerings. Attendees at MODEX 2024 demonstrated a strong inclination towards investing in innovative technologies, particularly in automated guided vehicles (AGVs) and autonomous mobile robots (AMRs).

Businesses Poised to Invest in Automation

Like many AGV providers, we’ve seen the interest in AGV solutions increase every year at MODEX and ProMat, but this year it’s clear that businesses are in the market to adopt AGVs like never before.

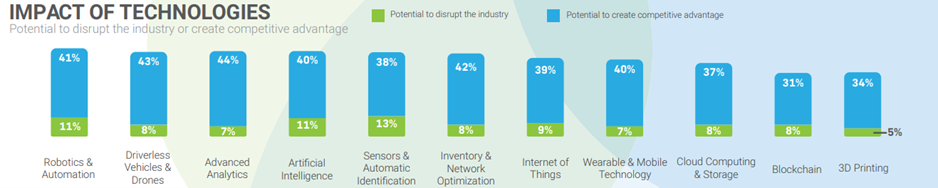

Of all supply chain technologies listed, robotics and automation have the highest potential to disrupt the industry and create a competitive advantage according to MHI’s 2024 Annual Industry report.

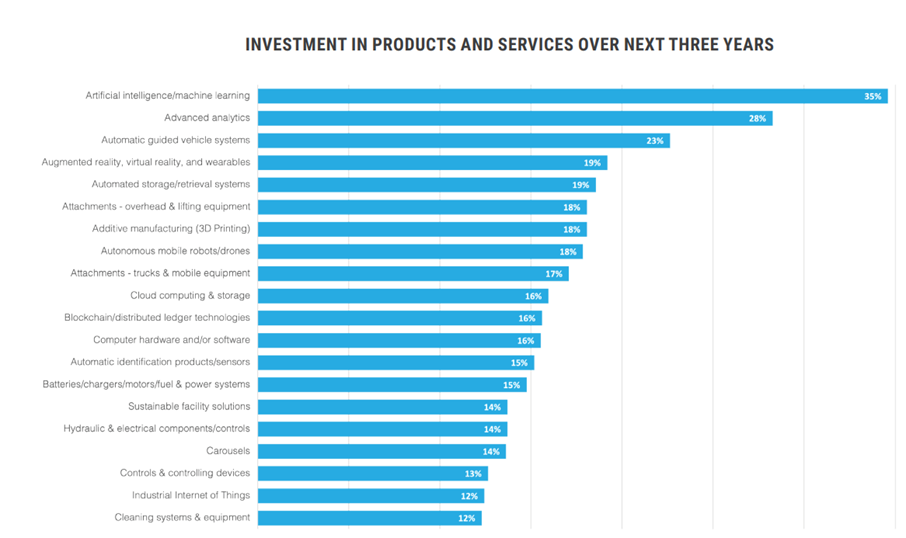

Of all respondents, 23% plan to invest in automated guided vehicle systems in the next three years. The survey also revealed that 55% of respondents have increased their investments, with 88% planning to spend over $1 million and 42% planning to spend over $10 million in supporting equipment, systems, and technology.

We saw this echoed in discussions at our booth, with attendees consistently looking to automated solutions such as AGVs to streamline repetitive and inefficient tasks. Two of the main applications attendees were looking to utilize AGVs to drive greater efficiency were:

- Towing AGVs to tow multiple carts through the facility to facilitate lineside deliveries and improve operational efficiency.

- The use of unit load AGVs to deliver greater efficiency in material movement and mitigate space constraints.

#2 Addressing Industry Challenges with Innovative Solutions

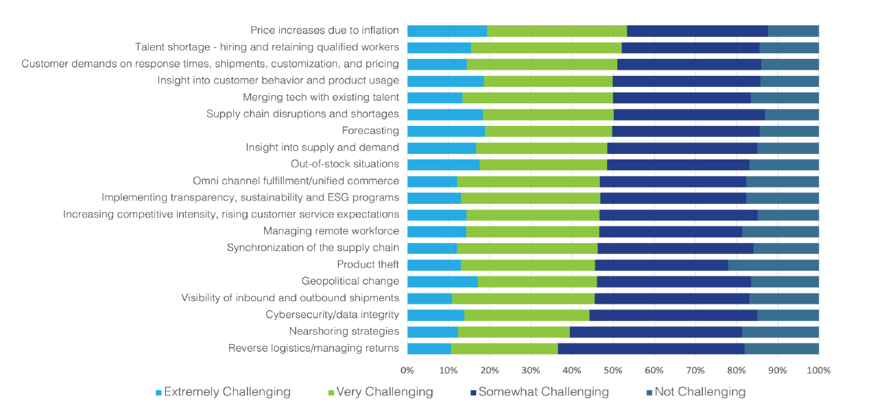

As outlined in the MHI Industry Report, global talent shortages and evolving customer demands continue to challenge manufacturers. Attendees stressed that they were looking for agile and efficient material handling systems that enhance productivity and flexibility.

#3 Promoting Collaboration between Humans and Technology

As the MHI report demonstrates, the challenge of hiring and retaining a skilled workforce remains a stumbling block for manufacturers.

During our discussions with attendees at MODEX, it was clear that many businesses are looking to innovative technologies to work alongside staff – and crucially, enable staff to work on more productive and value-adding activities. The mood at MODEX was focused on promoting collaboration between humans and technology, with attendees highlighting their desire to utilize automation technology to make work more efficient, easier, and safer for staff.

Looking Ahead to ProMat 2025

With the exhibits and branding packed away, we’re looking ahead to ProMat 2025 in Chicago next year. But what can we expect to see in the next 12 months? In addition to the challenges and trends outlined in the 2024 MHI Annual Industry Report, our team got together to highlight three key predictions for the next 12 months, taking insight from daily conversations with manufacturers and supply chain professionals across the United States.

Our Predictions

-

Foot on the gas for AGV adoption in US manufacturing

As the MHI report has confirmed, businesses are looking to increase their adoption of automation like never before. We speak to manufacturers across industrial manufacturing day-in, day-out and our conversations echo these statistics, with businesses focusing on the implementation of AGVs.

-

Automation of heavier payloads and applications

As the continued adoption of automation gains pace and diversifies into new industries and applications, AGVs and other automated vehicles are also being utilized to move heavier payloads. With an AGV range capable of moving up to 154,000 lbs. we’re working with leading industrial manufacturers to deliver powerful, high-capacity AGV solutions.

-

Outdoor AGVs are no longer a pipe dream

For as long as there has been interest in automated guided vehicle solutions, there has been an appetite for AGVs that can reliably navigate outdoors. Now, as more manufacturers look to accelerate their AGV adoption, outdoor navigation is no longer simply a ‘nice to have’. Utilizing best-in-class GNSS outdoor navigation, our range of outdoor AGVs are trusted by manufacturers to operate autonomously outside safely and reliably, over rough terrain and in challenging weather conditions.

In summary, MODEX 2024 underscored the growing momentum towards automation, particularly in AGV adoption, as businesses seek to address industry challenges and enhance efficiency. Looking beyond MODEX 2024, the focus on AGV adoption is expected to intensify, particularly when it comes to handling heavier payloads and the advent of outdoor AGVs.

For deeper insights into leveraging our trusted range of AGVs to drive efficiency, reach out to us and let's shape the future of your material handling together.