Guilford Textiles Increase Efficiency with Four Tugs

Automotive fabrics manufacturer Guilford Performance Textiles, part of the Lear Corporation, has extended its use of MasterMover electric tugs with the purchase of an additional four models, in a drive to further improve logistical efficiency on the shop floor.

Guilford Performance Textiles runs a complex operation involving multiple processes, whereby purpose-woven yarn – created especially for the automotive industry – is fabricated to form heavy-duty coverings for interior fittings and surfaces.

A heavy challenge

Weaving, treating, bleaching, and colouring procedures transform the yarn into suitable fabric with each process occurring within a different part of the manufacturing plant.

This necessitates the safe transportation of heavy material in various forms across the factory floor – and for that, appropriate handling assistance is essential, as Guy Baggaley, lean engineer at Guilford Performance Textiles, explains:

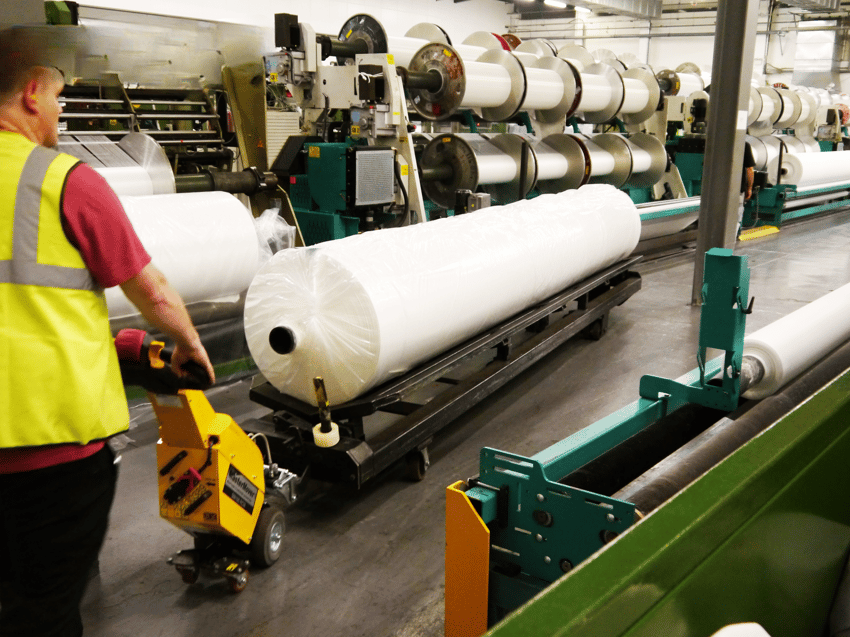

The rolls of material we work with are hefty, and can each weigh as much as 2,000kg. Manoeuvring such heavy loads in an indoor environment is a challenge that needs to be addressed with health and safety considerations as a main priority.

Guy BaggaleyLean Engineer, Guilford Performance Textiles

Guilford Performance Textiles have trialled alternative transportation solutions to no avail, and with a growing focus on the safety of the site this proved to be a more difficult problem, as Guy explains further:

“Other factory floor transportation solutions have been trialled: for example, pallet trucks were used temporarily, but considered far from ideal. At the same time, for health and safety reasons, limitations were put in place on the factory floor to reduce the amount of ride-on traffic,”

Time for a smarter solution

The longstanding relationship with MasterMover dates back 10 years, when a third party originally recommended the company’s pedestrian-operated electric tugs as a suitable solution for safe, reliable movement of textile rolls.

As business has evolved the demand for additional power-assisted equipment has also grown and Guilford Performance Textiles has now ordered a mix of MasterTugs and SmartMovers to suit the requirements of different departments.

MasterTugs are MasterMover’s flagship solution for transporting mid-range heavy loads, available in a number of specification levels tailored to meet specific requirements. Accordingly, Guilford Textiles has chosen models appropriate to its particular challenges, ensuring that each MasterTug is optimised for its role.

These are complemented with the purchase of several SmartMovers, the company’s versatile solution for smaller loads, which can safely and effectively move up to 2,000kg.

Both operate on the same principle of using weight transfer to generate traction, which enables a single pedestrian operator to manoeuvre loads with ease and control, even within environments that require transportation beyond the smooth factory floor.

Powerful change

“In terms of power, simplicity, manoeuvrability and versatility, it was clear that MasterMover offered the most effective solution to our needs and we have full confidence adding further electric tugs to our inventory,” he adds. “I wouldn’t hesitate in recommending MasterMover for their equipment and service. Quite simply, their tugs are the right tools for the job.”

Andy Owen, Managing Director of MasterMover, is delighted that Guilford Performance Textiles has kept faith in electric tugs after a decade of successful experience.

“To receive such a seal of approval from a fellow British manufacturer is gratifying, as we pride ourselves on delivering reliable solutions that are designed and made in Britain by engineers with a real understanding of the needs of each individual customer.”