Mobilising Lean Manufacturing in the Automotive Industry with the Toyota Production System (TPS)

Lean manufacturing is a philosophy that emphasises reducing waste and streamlining processes to improve efficiency.

The automotive industry has been using lean techniques for decades, but how can electric tow tugs help manufacturers accelerate their production efficiency?

This article will explore:

The Toyota Production System (TPS)

Moving on from the design of the first moving assembly line by Henry Ford in 1913, mechanised processes and equipment are well-embedded within automotive manufacturing.

As automotive manufacturing dialled up in the 1950s, the Toyota Motor Corporation developed the Toyota Production System (TPS) – a philosophy of eliminating waste within the manufacturing process.

The system is centred around two core principles – Just-In-Time and Jidoka.

Just-In-Time (JIT) manufacturing

Making only “what is needed, when it is needed, and in the amount needed” – Toyota

Just-In-Time (JIT) manufacturing is an approach to designing, scheduling, and managing manufacturing processes that minimise inventory levels while maximising production efficiency. By employing a just-in-time inventory management system, manufacturers can reduce costs by eliminating unnecessary inventory and optimising their production processes.

Jidoka

Automation with human intelligence

Jidoka is a principle that focuses on problem solving and continuous improvement by empowering employees to quickly identify problems and take action to eliminate them. This is designed to prevent defective products from being produced – reducing waste.

What is classed as waste in lean manufacturing?

Within lean thinking, eliminating waste is critical to maximising efficiency. Toyota classifies typical production wastes into three key areas Muda, Muri and Mura within the Toyota Production System.

Mura

Focuses on irregularities in the production process

Muri

Centres on the overburden of equipment and people

Muda

Covers a wide range of non-value-adding activities such as transportation and motion

What is Kaizen?

Kaizen is another key component of lean manufacturing principles that focuses on improving quality and efficiency through continuous improvement.

It aims to eliminate waste by creating a culture focused on identifying where improvements can be made, and then taking action to make those improvements.

Kaizen has been used successfully in the automotive industry to reduce lead times, increase productivity and decrease costs.

The challenges of implementing lean manufacturing

Implementing a lean manufacturing system is a continuous process that needs to be embedded within the company culture to succeed.

Some of the key challenges automotive manufacturers face when implementing lean manufacturing principles include gaining employee buy-in, dealing with resistance, managing change, measuring progress and ensuring quality standards are met.

A core challenge faced by automotive manufacturers we work with is balancing safety needs with productivity goals.

How electric tow tugs help manufacturers balance safety and efficiency

Reducing waste is core to lean thinking and as manufacturers seek to reduce wastes such as waiting, movement and underutilised workers, they are increasingly looking towards more efficient material handling solutions to support them.

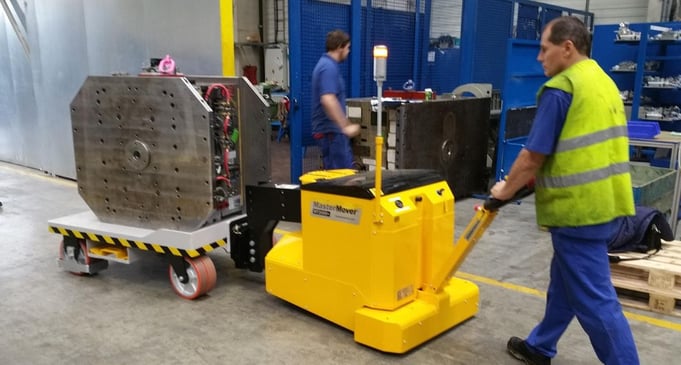

Electric tugs are a battery-powered material handling solution designed to take the strain when moving heavy wheeled loads such as kitting trolleys, moulds, body-in-white (BiW) and parts.

Here’s two examples of how electric tow tugs help automotive OEMs reduce waste:

Reduce Waiting

With no operator licence required, electric tugs help manufacturers reduce the wasted time in waiting for a licensed driver associated with traditional material handling equipment, such as forklift trucks or ride-on tow tractors.

For automotive manufacturers striving for even greater efficiency, our best-in-class autonomous electric tug solutions and AGV systems offer a solution designed for lean environments.

Reduce Underutilised Workers

Loads such as kitting trolleys or parts are often delivered to the line manually by operators. This is an ineffective use of time and people, and a waste that electric tugs are perfectly suited to address.

Equipment can be quickly and safely moved to the line, just-in-time, allowing staff to focus on greater value-adding tasks.

Autonomous Electric Tug at Toyota Motor Manufacturing

In line with lean principles, Toyota Motor Manufacturing have taken advantage of the benefits of an AGV system from MasterMover, to drive efficiency and reduce waste, whilst maximising safety standards.

The company is using a MasterMover AGV to transport resin back doors to the production line, delivering the parts when they are needed, before returning to the storage area to pick up the next batch – all without any human involvement.

Learn more in this video where the engineers involved in the project give an over of the solution and their experiences.

Balancing Safety & Efficiency

The automotive industry is no stranger to lean manufacturing techniques such as the Toyota Production System (TPS), Kaizen, and Just-In-Time (JIT) production.

These approaches have helped many automotive manufacturers cut costs while increasing efficiency, quality, and customer satisfaction.

As innovation within the automotive industry accelerates, manufacturers need to rely on dependable and safe equipment to support their lean processes. Global automotive OEMs and their tiered supply chain trust MasterMover electric tugs to support them in balancing safety and efficiency in their production processes.

With careful planning, a commitment to seeking out the right solutions, and an eye for innovation—the automotive manufacturer’s dream of achieving true operational excellence through lean principles can become a reality.