Continue reading

Continue reading

Transforming logistics operations to maximise efficiency

Logistics & Warehousing

Electric tugs help logistics providers increase operational efficiency, boost staff productivity and meet increasing customer demand…

The challenges of logistics and warehouse material handling

Rising consumer demand continues to add pressure on logistics providers and warehouses to maximise efficiency in replenishment and fulfilment processes. Logistics and warehouse material handling processes typically rely on a combination of manual handling and handling equipment such as forklifts and tow tractors.

Moving roll cages and other wheeled platforms of products by hand increases the risk of injury and lowers productivity, and likewise, waiting for a licensed driver to operate a forklift or tow tractor is inefficient and leads to bottlenecks.

Logistics providers looking to streamline operations need simple, reliable and flexible material handling solutions to maximise safety and operational efficiency.

Supercharge operational efficiency

Electric tugs empower a single operator to safely move heavy loads, reducing bottlenecks and maximising operational efficiency.

Streamlining the movement of loads, pedestrian operated and autonomous AGVs help logistics providers to meet demand and optimise intralogistics processes.

Eliminate manual handling and supercharge efficiency with effective warehouse material handling solutions...

The benefits of electric tugs in logistics and warehousing

Empowering a single operator to move heavy loads, electric tugs eliminate manual handling and increase productivity in warehouse material handling. Boasting a flexible design, electric tugs can be used to move multiple loads at once, maximising efficiency.

-

Eliminate manual handling

Electric tugs eliminate manual handling and reduce the risk of injury – maximising workplace safety.

-

Maximise productivity

Empowering a single operator to move loads, electric tugs maximise productivity, freeing up staff to work on more productive tasks.

-

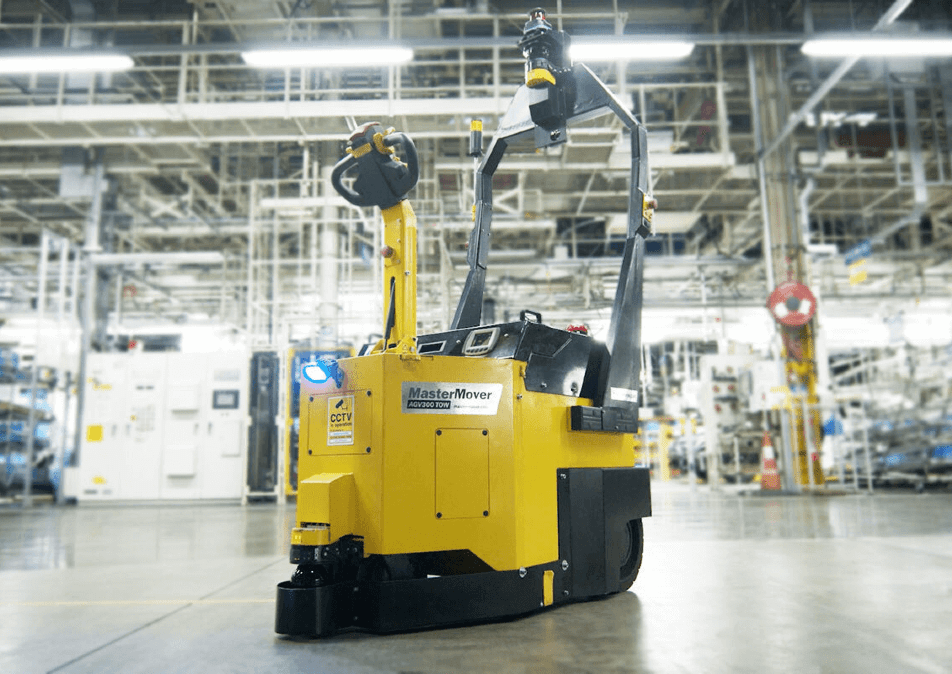

Automated handling solutions

Unlock greater efficiency by automating your warehouse material handling processes with our warehouse AGV.

Our range of logistics & warehousing electric tugs

AllTerrain

Up to 5,000 kg

Delivering powerful performance in demanding conditions, choose the AllTerrain range to safely move heavy loads on rails and castors.

MasterTug

Up to 20,000 kg

The MasterTug range allows a single pedestrian operator to easily push, pull and steer wheeled loads weighing up to 20,000kg.

MasterTow

Up to 20,000 kg

Drive safety and efficiency with our powerful electric tow tugs, designed to safely move loads of up to 20,000kg.

Automated warehouse material handling

Maximise operational efficiency with a warehouse AGV system

Looking to supercharge operational efficiency? Removing human involvement in material handling processes, our warehouse AGVs boost labour productivity and operational efficiency for distribution centres and fulfilment operations.

Trusted by leading logistics providers

Our electric tugs are trusted to drive operational efficiency and improve safety across the logistics industry, from global third-party logistics providers (3PL) to logistics warehouses, you’re in safe hands.

Since using the tugs, we’ve seen a significant reduction in the number of roll cage-related handling injuries to delivery drivers of 42 per cent.

Dave TaylorHealth & Safety Manager, Spar Appleby Westward

Your Questions, Answered - FAQs

Electric tugs are used to move heavy-wheeled loads throughout the logistics industry. Whether it’s the movement of full cages for distribution or moving nested cages back to fulfilment, electric tugs are relied on to support safe, efficient intralogistics processes across the industry.

No, unlike traditional lifting equipment such as pallet trucks and forklifts, electric tugs do not lift loads off the ground. Electric tugs are designed to move wheeled loads, delivering the safe, efficient and flexible movement of loads.

Ideally suited to working within the logistics industry, electric tugs can be used to complement and enhance existing material handling processes, working alongside lifting equipment to support efficient and safe intralogistics.

No, electric tugs do not require a license to operate. A license-free operation makes electric tugs an attractive option for logistics providers and warehouses looking to streamline the movement of loads and improve safety.

Minimal training is required to safely operate an electric tug and we offer training packages to suit every requirement.

Electric tugs are battery powered, with interchangeable batteries or lithium options available, electric tugs can deliver 24/7 operation to keep your processes moving.

Offering zero emissions from the point of use, electric tugs are ideally suited for indoor use.

We're here to help

If you’re looking to improve safety, remove the risk of injury and unlock greater operational efficiency, we’re here to help. Speak to our team to discuss your application.

Interested in learning more? Read the latest articles

Continue reading

Continue reading

How retail and logistics companies can minimise risk when using roll cages