Continue reading

Continue reading

The power to maximise control of sensitive equipment

Nuclear

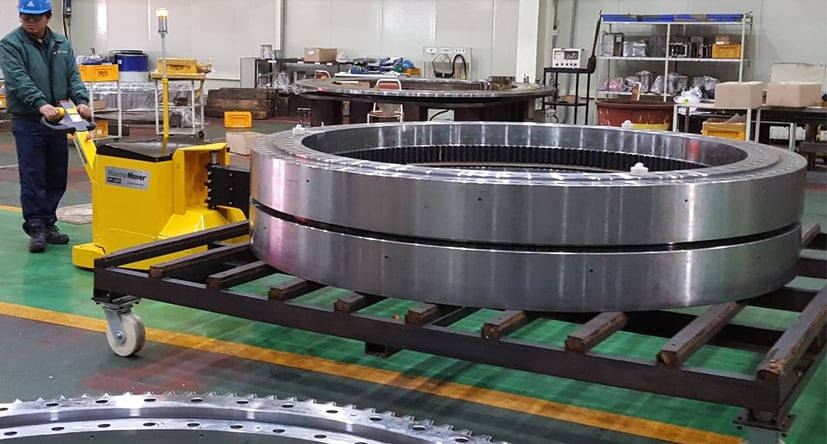

Delivering the controlled movement of sensitive loads and hazardous material, MasterMover electric tugs are trusted by nuclear energy providers to safely move equipment.

Moving hazardous materials needs precise control

Handling hazardous materials and sensitive loads in the nuclear sector can be a challenge.

Highly regulated and controlled environments mean that manual handling is often relied on to move heavy-wheeled loads – presenting the risk of injury.

Moving heavy vessels and tanks puts staff at risk, leading many nuclear providers to turn to electric tugs.

Powering up safety in nuclear

Electric tugs enable operators to safely control heavy-wheeled loads, eliminating the need for manual handling.

Compact and powerful, a single operator can precisely move heavy loads weighing over 70,000kg with complete control, reducing the risk of damage and maximising safety.

The benefits of electric tugs for nuclear

Safe, secure and controlled, electric tugs ensure loads are moved with accuracy and stability – reducing the risk of collisions.

-

Maintaining a safe distance

Electric tugs take the manual element out of movement, allowing operators to stand further away from the load being moved – minimising contact.

-

Maximise productivity

Using electric tugs empowers highly skilled staff to focus on tasks of greater value add, improving morale and productivity.

-

A secure connection, every time

Robust and secure coupling systems ensure loads remain connected, guaranteeing total load security and maximising control.

Our range electric tugs for nuclear environments

MasterTug

Up to 20,000 kg

The MasterTug range allows a single pedestrian operator to easily push, pull and steer wheeled loads weighing up to 20,000kg.

MasterTow

Up to 20,000 kg

Drive safety and efficiency with our powerful electric tow tugs, designed to safely move loads of up to 20,000kg.

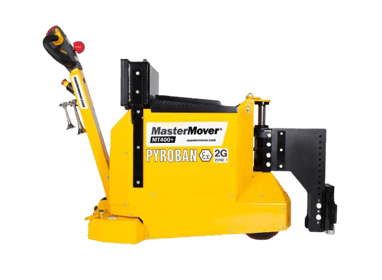

ATEX/IECEx

Up to 70,000 kg

Durable electric tug solutions for hazardous environments.

Remote Control Technology

Hands-free movements to maximise safety

The controlled movement of hazardous materials with electric tugs – but with the added benefit of remote control operation.

Remote control operation enables operators to stand away from the load and take up the ideal vantage point, unlocking greater visibility and allowing operators to maintain a safe distance from loads.

Trusted by industry leaders

Quality assurance is crucial. That’s why leading nuclear research facilities and power plants trust MasterMover electric tugs to deliver the controlled movement of hazardous loads and high-value equipment.

MasterMover are easy to work with and all products performed as advertised. Moved our heavy products with ease!

Parker MacciantiMechanical Engineer

Your Questions, Answered - FAQs

- Stainless steel vessels

- Hoppers and bins

- Components and support equipment

Electric tugs are used by nuclear facilities to improve safety when moving loads such as:

Yes, all of our electric tugs can be converted to meet ATEX standards. Our electric tugs can be converted to operate in zones 1 and 2 (gaseous explosive environments) and zones 21 and 22 (powder or dust explosive environments) to meet ATEX and IECEx standards.

Working with best-in-class explosion-proofing providers, MasterMover ATEX electric tow tugs can safely work in hazardous environments, allowing you to maximise workplace safety and efficiency.

Electric tugs are battery powered, with interchangeable batteries or lithium options available, electric tugs can deliver 24/7 operation to keep your processes moving. Offering zero emissions from the point of use, electric tugs are ideally suited for indoor use, replacing internal combustion engine (ICE) powered equipment such as forklifts or tow tractors.

A range of coupling options are available across the range that maximise performance, security and safety.

Custom coupling solutions can also be designed for unique applications.

We're here to help

If you’re looking to improve safety, remove the risk of injury and unlock greater operational efficiency, we’re here to help. Speak to our team to discuss your application.

Interested in learning more? Read the latest articles

Continue reading

Continue reading

Moving Wind Turbine Blades During Manufacturing