Continue reading

Continue reading

Shifting efficiency up a gear

Automotive & Commercial Vehicles

Electric tugs allow automotive manufacturers to create leaner, more efficient production lines and safer working environments..

Struggling with production bottlenecks?

Time is money in automotive and commercial vehicle manufacturing. For large loads like body-in-whites, chassis and body panels, waiting around for a licensed forklift or tow tractor driver results in downtime and delays. The manual delivery of kitting trolleys lineside takes staff away from value-adding tasks and increases the risk of injury and fatigue.

Accelerating efficiency and safety in automotive manufacturing

Reducing the reliance on traditional material handling equipment and eliminating manual handling, electric tugs allow operators to move equipment just-in-time, driving operational efficiency. With no operator license required, there’s no wasted time in waiting for a licensed driver, maximising productivity and production flow. AGV solutions are also available to drive maximum efficiency, removing the need for human involvement.

The benefits of electric tugs for automotive manufacturing

You need material handling solutions that enhance production processes, not hinder them.

Electric tugs offer a flexible solution enabling the efficient, safe movement of equipment and loads throughout production facilities.

-

Create leaner processes

Internal transportation is a non-value-adding process. License-free electric tugs streamline the movement of loads to create leaner processes.

-

Maximise staff productivity and safety

Using electric tugs empowers highly skilled staff to focus on tasks of greater value add, improving productivity and eliminating manual handling.

-

Unlock greater flexibility

Electric tugs can be used to foster modular production processes or scalable pulse lines – offering greater flexibility than fixed alternatives.

Our range of automotive electric tugs

SmartMover

Up to 2,000 kg

Compact but powerful, the SmartMover is the ideal manual handling solution – trusted to improve safety across industrial manufacturing, retail and ...

MasterTug

Up to 20,000 kg

The MasterTug range allows a single pedestrian operator to easily push, pull and steer wheeled loads weighing up to 20,000kg.

MasterTow

Up to 20,000 kg

Drive safety and efficiency with our powerful electric tow tugs, designed to safely move loads of up to 20,000kg.

PowerSteered

Up to 70,000 kg

Remote control solutions for maximum visibility when moving loads up to 70,000kg, and beyond with our patented MultiLink solution.

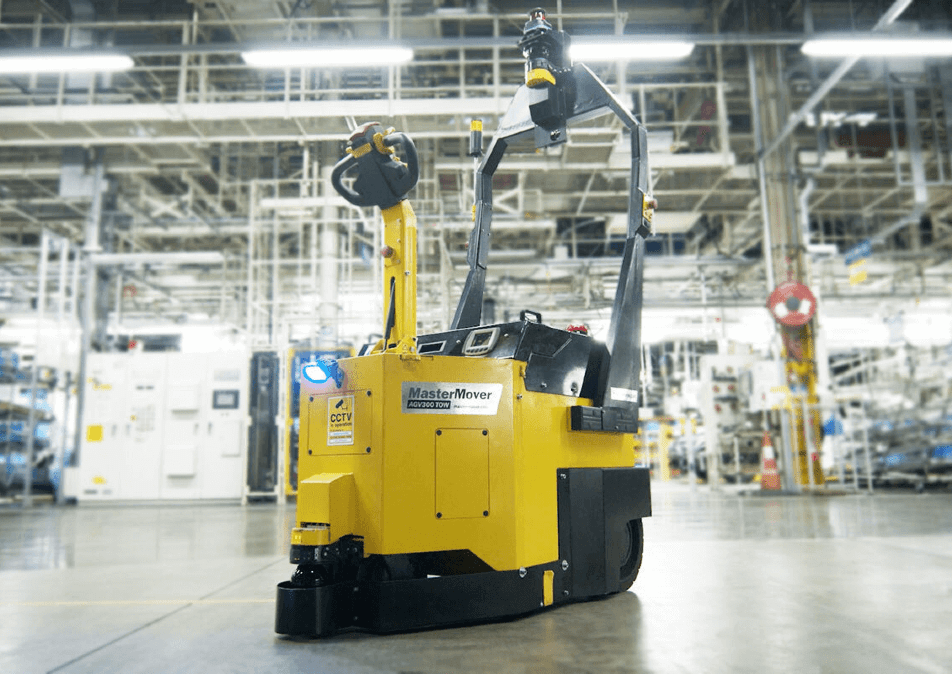

AGV Systems – Case Study

Toyota accelerates efficiency with an AGV system

A world leader in its field, the automotive manufacturer has achieved return on investment and improved operational efficiency when moving parts to the production line…

Learn how Toyota Motor Manufacturing used an AGV system to automate its driving processes.

Trusted by global automotive and commercial vehicle OEMs

With an expansive customer base made up of the world’s leading automotive manufacturers, you’re in safe hands.

I’d certainly be happy to recommend the MasterMover AGV to other organisations looking to automate their driving processes.

Kevin JonesPrincipal Engineer Assembly Engineering, Toyota Motor Corporation

Your Questions, Answered - FAQs

- Body panels, body-in-whites and chassis

- Kitting trolleys

- Injection moulds and tooling

- Powertrains and gearboxes

- Pedestrian operated electric tugs allow a single operator to safely manoeuvre even the heaviest loads with confidence, removing manual handling and reliance on forklift trucks.

- Remote control operation is available to deliver maximum visibility by allowing operators to take up the ideal vantage point when moving loads, facilitating the seamless movement of loads in congested areas.

- Automated AGV electric tugs remove the need for an operator, automating the movement of heavy loads to maximise efficiency and resource utilisation.

Across automotive manufacturing, electric tow tugs are used to move a wide variety of tooling, components and equipment, including loads such as:

Electric tugs are available with multiple control options designed to suit the needs of modern automotive manufacturing:

No, unlike lifting equipment such as forklift trucks and cranes, an electric tug does not require a license to operate. A license-free operation reduces downtime and maximises operational efficiency, reducing wasted time waiting for a licensed driver.

Minimal training is required to safely operate an electric tug and we offer training packages to suit every requirement.

Electric tugs are battery powered, with interchangeable batteries or lithium options available, electric tugs can deliver 24/7 operation to keep your processes moving.

Offering zero emissions from the point of use, electric tugs are ideally suited for indoor use, replacing internal combustion engine (ICE) powered equipment such as forklifts or tow tractors.

A range of coupling options are available across the range that maximise performance, security and safety. Custom coupling solutions can also be designed for unique applications.

We're here to help

If you’re looking to improve safety, remove the risk of injury and unlock greater operational efficiency, we’re here to help. Speak to our team to discuss your application.

Interested in learning more? Read the latest articles

Continue reading

Continue reading

Tow Tugs See Johnston Sweepers Reduce Waiting Times