AllTerrain

Up to 5,000kg

Up to 5,000kg

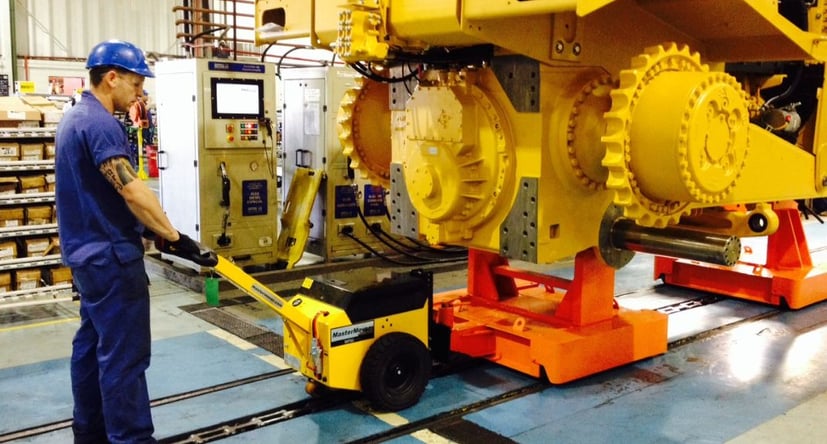

A heavy-duty solution for load movement in the most challenging environments…

The AllTerrain range enables the safe movement of heavy-wheeled loads weighing up to 5,000kg. Featuring an intuitive design, this range enables a single operator to easily push and pull loads with zero physical effort. With a design focused on durability and performance even in tough environments, the AllTerrain range can work outside on rough flooring and on slopes.

The AllTerrain range is suited to move heavy loads on both castors and rails. With a range of couplings available, units can be used as plug-and-play pushers or to push, pull and steer heavy loads.

An optional remote control system is available to improve visibility and ease of pushing and pulling heavy loads during linear movements. An adjustable coupling height makes the range easy to integrate with existing systems and equipment.

AllTerrain Key Features

The AllTerrain range is packed full of features that maximise operator safety when moving loads on castors or rails.

Safety

- Audible horn, flashing beacon, performance monitoring and emergency stop

-

Speed control with optional two-speed selector switch

- Optional remote control for maximum visibility on linear movements

Performance

- Heavy-duty industrial units able to work on rough terrain

- Puncture-proof, non-marking drive wheels able to gain traction on rough floor surfaces

- Durable design suited for working in the toughest of environments

Power

-

Powerful AC motor optimises both speed and power

-

Adaptable motor able to operate at slow and fast speeds and different acceleration rates

-

High-performance AGM maintenance-free batteries

Connection

-

Range of coupling options suited to moving loads on rails and castors

-

Custom coupling designs available for specialist needs

-

Secure bolt-on couplings for applications requiring controlled, powerful pulling movements

- Plug-and-play coupling options to push heavy wheeled loads

Explore the AllTerrain Range

The AllTerrain range can be used to remove manual handling or create more flexible, efficient production processes.

Custom solution available, contact us here.

ATT400+

- Load capacity 5000 kg

- Maximum slope 10 degrees

- Max distance per charge (standard battery) 12.1 km

- Charge time (external charger) 8.25h

- Maximum push force 400 kg

- Maximum pull force 350 kg

- Standard IP rating IP44

- Dimensions (w x l x h) 750 x 1687 x 1165 mm

- Interchangeable battery No

- Lithium battery Yes

- Stainless steel No

- ATEX Yes

MP400

- Load capacity 5000 kg

- Maximum slope 15 degrees

- Max distance per charge (standard battery) 13.4 km

- Charge time (external charger) 7.5h

- Maximum push force 400 kg

- Maximum pull force 0 kg

- Standard IP rating IP44

- Dimensions (w x l x h) 750 x 1632 x 979 mm

- Interchangeable battery Yes

- Lithium battery Yes

- Stainless steel No

- ATEX Yes

ATP400

- Load capacity 5000 kg

- Maximum slope 10 degrees

- Max distance per charge (standard battery) 12.1 km

- Charge time (external charger) 8.25h

- Maximum push force 400 kg

- Maximum pull force 350 kg

- Standard IP rating IP44

- Dimensions (w x l x h) 750 x 1551 x 1165 mm

- Interchangeable battery Yes

- Lithium battery Yes

- Stainless steel No

- ATEX Yes

Download technical datasheet

Safety & machine options

Whether you need to move trains of nested roll cages or sub-assemblies on the production line, the powerful, compact AllTerrain range is the ideal solution.

L-shaped push plate

A safe and simple design is perfect for pushing loads on rails.

Height adjustable push plate

Easily push a range of loads at different heights on rails.

York roll cage coupling

Easily push trains of nested York roll containers

Tetra roll cage coupling

Safely push trains of nested Tetra cages

Box coupling

Benefit from a secure connection, perfect for rough surfaces with the BoxCoupling system.

Fifth wheel

Delivers precise movements when pushing alongside box coupling set-up.

Custom couplings

Need something different? We can design custom couplings to suit your application.

High-capacity batteries

Increased capacity batteries for longer performance.

Lithium battery options

Power when you need it, enabling opportunity charging for demanding applications.

Battery protection system

Maximise your battery service life by preventing battery damage.

External chargers

Guarantees fast, optimised charging for fixed locations.

Internal onboard charger

Our onboard chargers provide flexible charging when you need it.

Two speed selector switch

Adjustable speed settings at your fingertips.

Safety light beeper

Maximise safety when moving loads through congested areas.

Emergency stop

Allows you to immediately stop the machine.

Anti-crush button

Protect operators and maximise operator safety when moving loads.

Warning horn

Perfect for congested areas, alert pedestrians when moving loads.

Remote control

Maximise visibility when moving loads in straight lines or on rails.

With the help of the MasterMover team, we found a device that met our requirements – namely very manoeuvrable, even with a heavy load, easy to use and capable of adapting to all terrains such as climbs, bumps and slippery floors.

Joel OddouxHSE Manager, Sicarev

Benefits of the AllTerrain Range

Moving heavy loads in challenging environments? The AllTerrain range is ready to work, right out of the box, even in the toughest environments – powering efficiency and workplace safety one move at a time.

Safe movement of loads weighing up to 5,000kg

License-free operation

Zero emissions

Compact machines for tight spaces

Secure movement of loads

Eliminate manual handling

Suitable for indoor and outdoor use

Easy and secure couplings

Your Questions, Answered – FAQs

Yes, MasterMover electric tugs can be used outside. Built with durability in mind, the AllTerrain range delivers optimum traction.

Purpose-built for the most challenging industrial environments, the AllTerrain range can be used inside, outside and on slopes.

The AllTerrain range is used in a range of environments, from retail to rolling stock maintenance. The range boasts flexible solutions to move heavy loads on rails to reduce the reliance on fixed infrastructure or forklift trucks.

Likewise, the range is used within retail logistics to move trains of nested roll cages without the need for manual handling.

The remote control operation of the AllTerrain range enables operators to take up the ideal vantage point when moving loads in straight lines. Simple controls allow operators to move the machine and load from a distance – ideal for moving loads on rails or when moving trains of nested roll cages in retail distribution.

With the Two Speed Selector switch, ‘Tortoise’ mode enables you to maximise control and operate the machine at a slower speed setting of 1.2kph. In the faster ‘Hare’ setting, the machine’s speed is 3kph.

Machines can be set with custom speed settings where required, with a maximum programmable speed of 6kph.

Battery performance varies from model to model and is influenced by load weight, battery capacity, environmental conditions and usage. Individual battery performance data can be found on the Technical Specification Sheets for each model.

A range of coupling options are available across the range that maximise performance, security and safety.

Custom coupling solutions can also be designed for unique applications.

Yes, the AllTerrain range can work safely on slopes. When it comes to electric tugs, it’s important to understand that for every degree of slope involved, the maximum load capacity of the machine is reduced, just as pushing a car on the level requires less force than on a slope.

Therefore, if the weight of the load is already close to the maximum capacity of the machine, a more powerful machine may be needed to move the load on a slope.

We carry out a full evaluation of your application to ensure any machine is suited to your needs.

Sectors we work in

Aerospace

Unlock safer material handling processes in the aerospace industry with electric tugs.

Energy & Petrochemical

Maximum performance and manoeuvrability of heavy loads in the energy industry.

Automotive & Heavy Plant

Choose electric tugs to enhance lean processes and increase shop floor flexibility.

Food & Beverage

Eliminate manual handling with electric tugs for safer food material handling – maximising efficiency and reducing the risk of injuries.

Retail, Logistics & Warehousing

The ideal manual handling solution to maximise efficiency and safety within retail and logistics.

Pharmaceutical & Life Sciences

Safely manoeuvre heavy, high-value equipment, eliminating manual handling and maximising production efficiency.

Facilities & Waste

Eliminate manual handling and maximise safety in facilities and waste management.

Manufacturing & Assembly

Industrial manufacturers trust electric tugs to improve workplace safety and supercharge operational efficiency.

Ready to Unlock Safer Operations?

Are you looking to improve safety and efficiency in your operations? Contact us to discover how you could transform your processes to enhance efficiency and maximise workplace safety with an electric tug or electric tow tug.

Related products

SmartMover

Up to 2,000 kg

Compact but powerful, the SmartMover is the ideal manual handling solution – trusted to improve safety across industrial manufacturing, retail and ...

MasterTow

Up to 20,000 kg

Drive safety and efficiency with our powerful electric tow tugs, designed to safely move loads of up to 20,000kg.

MasterTug

Up to 20,000 kg

The MasterTug range allows a single pedestrian operator to easily push, pull and steer wheeled loads weighing up to 20,000kg.

PowerSteered

Up to 70,000 kg

Remote control solutions for maximum visibility when moving loads up to 70,000kg, and beyond with our patented MultiLink solution.

.jpg?width=827&height=559&name=ATP400-electric-tug-heavy-plant-jcb%20(2).jpg)