Continue reading

Continue reading

Safe control of delicate loads for brick and ceramic manufacturers

Brick & Ceramic

Electric tugs enable a single operator to safely move loads such as kiln carts, moulds and completed product with total control, improving workplace safety and reducing the risk of damage to loads.

Material handling challenges in brick and ceramic manufacturing

Within the manufacture of bricks and ceramics, heavy, fragile loads can make finding suitable material handling solutions a challenge.

With manufacturers often relying on a combination of manual handling and forklift trucks to push loads such as heavy kiln carts, the risk of product damage is high.

Safety Managers looking to remove the risk of injury are increasingly looking for safer solutions for moving heavy loads in brick and ceramic factories.

Controlled movement of loads for maximum safety

Enabling a single operator to move loads of 70,000kg and beyond, electric tugs enable brick and ceramics manufacturers to reduce the risk of product damage and improve workplace safety.

With no operator license required, loads can easily be moved as and when required, optimising production flow.

Robust designs guarantee the powerful, controlled movement of loads, delivering unrivalled visibility – perfect for moving loads into kilns and positioning completed products.

The benefits of electric tugs in brick and ceramics

Compact but powerful electric tugs enable brick and ceramic manufacturers to safely move loads such as kiln cars, moulds, oven kilns, other materials and completed products with complete confidence.

-

Greater control of loads

Enabling the smooth, controlled movement of heavy loads, electric tugs reduce the risk of damage to products.

-

Safer movement of loads

Purpose-built for moving heavy-wheeled loads, electric tugs improve workplace safety and reduce the risk of injuries.

-

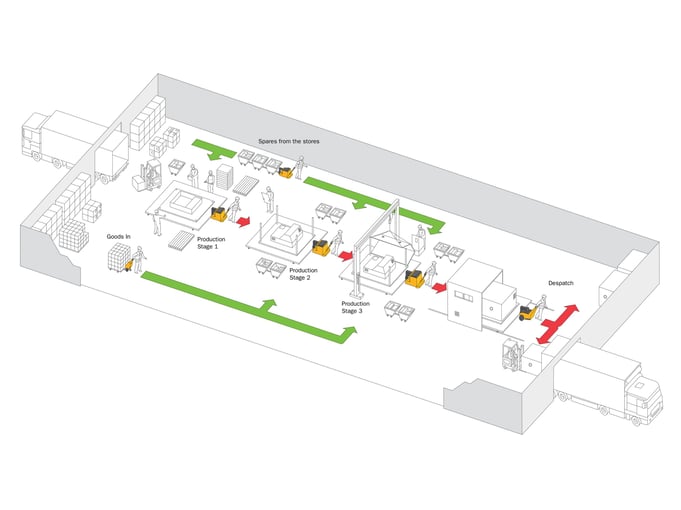

Maximise production efficiency

With no operator license required, a single operator can easily move loads as and when required – reducing downtime and production bottlenecks.

Our range of brick & ceramic moving electric tugs

SmartMover

Up to 2,000 kg

Compact but powerful, the SmartMover is the ideal manual handling solution – trusted to improve safety across industrial manufacturing, retail and ...

AllTerrain

Up to 5,000 kg

Delivering powerful performance in demanding conditions, choose the AllTerrain range to safely move heavy loads on rails and castors.

MasterTug

Up to 20,000 kg

The MasterTug range allows a single pedestrian operator to easily push, pull and steer wheeled loads weighing up to 20,000kg.

MasterTow

Up to 20,000 kg

Drive safety and efficiency with our powerful electric tow tugs, designed to safely move loads of up to 20,000kg.

Trusted by leading brick and ceramic manufacturers

Leading brick and ceramics manufacturers trust MasterMover electric tugs to deliver the safe, controlled movement of heavy loads – allowing them to improve production efficiency and workplace safety.

MasterMover are easy to work with and all products performed as advertised. Moved our heavy products with ease!

Parker MacciantiMechanical Engineer,

Your Questions, Answered - FAQs

No, unlike lifting equipment such as forklift trucks and cranes, an electric tug does not require a license to operate. A license-free operation reduces downtime and maximises operational efficiency, reducing wasted time waiting for a licensed driver.

Minimal training is required to safely operate an electric tug and we offer training packages to suit every requirement.

Electric tugs are battery powered, with interchangeable batteries or lithium options available, electric tugs can deliver 24/7 operation to keep your processes moving.

Offering zero emissions from the point of use, electric tugs are ideally suited for indoor use, replacing internal combustion engine (ICE) powered equipment such as forklifts or tow tractors.

A range of coupling options are available across the range that maximise performance, security and safety.

Custom coupling solutions can also be designed for unique applications.

We're here to help

If you’re looking to improve safety, remove the risk of injury and unlock greater operational efficiency, we’re here to help. Speak to our team to discuss your application.

Interested in learning more? Read the latest articles

Continue reading

Continue reading

Trolley Handling Tug Eliminates FLT Use At Denso Marston