Continue reading

Continue reading

Supercharge your production line with total control

Aerospace Manufacturing

Global aerospace manufacturers trust MasterMover electric tugs to deliver the safe, controlled movement of high-value loads and equipment.

The power and precision you need to move high-value loads

High-value loads, large equipment and tight manufacturing areas are just a few aspects of aerospace manufacturing that challenge material handling in the industry.

Heavy-wheeled loads are often moved using lifting equipment, such as forklift trucks, tow tractors or overhead cranes, resulting in the risk of collisions, damage to equipment and production bottlenecks.

Aerospace manufacturers need material handling solutions that deliver the safe, controlled movement of equipment…

Maximum control and efficiency with license-free electric tugs

Electric tugs enable aerospace manufacturers to safely control heavy-wheeled loads and cut downtime through a license-free design.

Compact and powerful, a single operator can precisely move loads such as aero engines, wings and aero structures of 70,000kg and beyond - all with complete control, reducing the risk of damage and maximising safety.

Supercharge production efficiency with electric tugs

Whether it’s in the movement of jigs or the precise positioning of aerostructures and composites, electric tugs help aerospace manufacturers drive production efficiency.

A license-free operation reduces downtime, whilst a compact, intuitive design maximises safety and control.

-

Confidently manoeuvre loads to remove the risk of damage

Maximum visibility empowers operators to push, pull, and position loads with complete confidence - reducing the risk of damage.

-

Taking safety to new heights

Electric tugs improve workplace safety by eliminating manual handling and reliance on large material handling equipment.

-

Smooth, controlled movement of 70,000kg loads and beyond

Powerful performance and intuitive controls guarantee the controlled movement of high-value loads.

Our range of aerospace electric tugs

SmartMover

Up to 2,000 kg

Compact but powerful, the SmartMover is the ideal manual handling solution – trusted to improve safety across industrial manufacturing, retail and ...

MasterTug

Up to 20,000 kg

The MasterTug range allows a single pedestrian operator to easily push, pull and steer wheeled loads weighing up to 20,000kg.

MasterTow

Up to 20,000 kg

Drive safety and efficiency with our powerful electric tow tugs, designed to safely move loads of up to 20,000kg.

PowerSteered

Up to 70,000 kg

Remote control solutions for maximum visibility when moving loads up to 70,000kg, and beyond with our patented MultiLink solution.

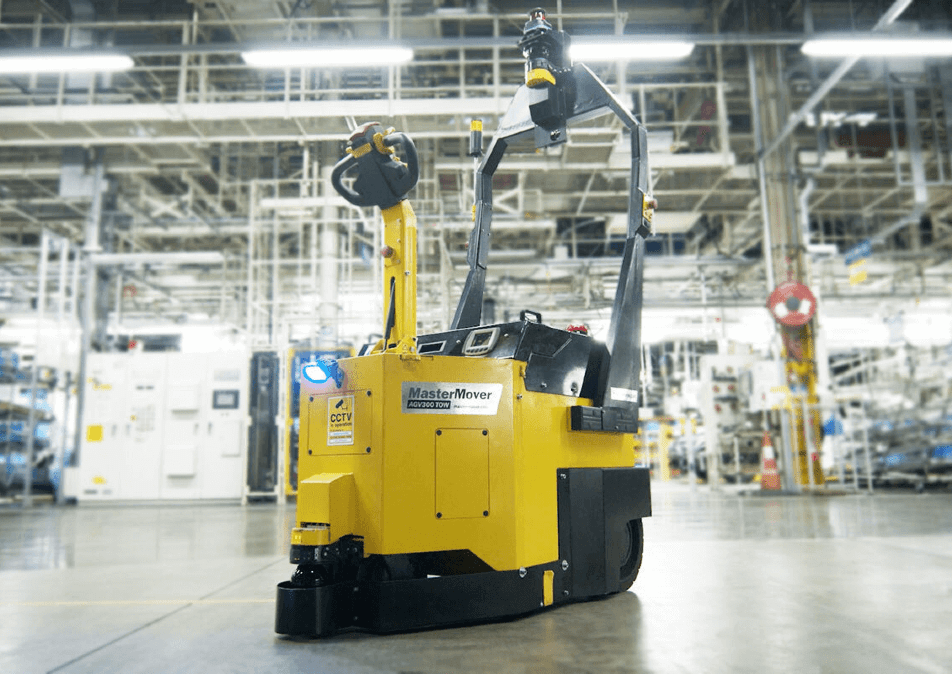

Automated Guided Vehicles for Aerospace

Maximise production efficiency and accuracy with aerospace AGV systems

Our AGVs deliver the predefined, controlled movement of loads – without the need for an operator.

You can maximise efficiency and guarantee the safe and precise movement of high-value loads every time with our AGV system for the aerospace industry.

Trusted by industry leaders

Our electric tugs unlock efficiency and improve safety for the biggest aerospace manufacturers.

Trusted by industry leaders

Our electric tugs unlock efficiency and improve safety for the biggest aerospace manufacturers.

I’d certainly be happy to recommend the MasterMover AGV to other organisations looking to automate their driving processes.

Kevin JonesPrincipal Engineer Assembly Engineering, Toyota Motor Corporation

We have an MT600+ and an MT1000+, MasterMover always attend site on-time for any maintenance or issues, and are always very helpful. Everyone I've dealt with at MasterMover has been very knowledgeable and helpful.

David Uden-CorrickTest Cell Team Leader, Rolls-Royce

Your Questions, Answered - FAQs

- Jigs, moulds and tooling

- Aero engines and fan casings

- Components, parts and kitting trolleys

- Platforms and staging

Electric tugs are used by global aerospace manufacturers to improve efficiency and safety when moving loads.

Designed to deliver the controlled movement of aerostructures, wings and composites – electric tugs ensure loads are carefully moved, reducing the risk of damage.

Our material handling solutions are also used to move:

Electric tugs are battery powered, with interchangeable batteries or lithium options available, electric tugs can deliver 24/7 operation to keep your processes moving. Offering zero emissions from the point of use, electric tugs are ideally suited for indoor use, replacing internal combustion engine (ICE) powered equipment such as forklifts or tow tractors.

Yes, MasterMover electric tow tugs can be used outside. Built with durability in mind, our electric tugs deliver consistent traction and performance on uneven surfaces and rough floors.

A range of coupling options are available across the range that maximise performance, security and safety. Custom coupling solutions can also be designed for unique applications.

Yes, our electric tugs can work safely on slopes. When it comes to electric tugs, it’s important to understand that for every degree of slope involved, the maximum load capacity of the machine is reduced, just as pushing a car on the level requires less force than on a slope.

Therefore, if the weight of the load is already close to the machine’s maximum capacity, a more powerful machine may be needed to move the load on a slope. We carry out a full evaluation of your application to ensure that any machine is suited to your needs.

We're here to help

If you’re looking to improve safety, remove the risk of injury and unlock greater operational efficiency, we’re here to help. Speak to our team to discuss your application.

Interested in learning more? Read the latest articles

Continue reading

Continue reading

Aerospace Leaders Trust Electric Tugs