Mit Elektroschleppern schwere Lasten sicher & effizient bewegen

Elektroschlepper sorgen für die sichere, kontrollierte Bewegung schwerer, rollfähiger Lasten. Dank des kompakten Designs und weil keine Bedienerlizenz erforderlich ist, wird die manuelle Handhabung reduziert, Ihre Mitarbeiter werden geschützt und Sie verbessern die betriebliche Effizienz.

Vielen Dank für Ihr Interesse an unseren Produkten!

Ihre angeforderte MasterMover-Broschüre können Sie über den unten stehenden Link abrufen. Eine Kopie wurde Ihnen auch per E-Mail zugesandt.

Bitte kontaktieren Sie uns bei Fragen zu unseren Lösungen und Dienstleistungen.

Elektroschlepper – Die bessere Art, Produkte, Ausrüstung und Materialien zu bewegen

Elektroschlepper ermöglichen es einem einzigen Bediener, rollfähige Lasten mit einem Gewicht von bis zu 30.000kg und mehr zu bewegen. Dank einem umfassenden Angebot an Elektroschleppern, einschließlich handgeführten Mitgänger-Elektroschleppern, ferngesteuerten und autonomen FTS-Systemen, können Sie mit den Elektroschleppern von MasterMover für mehr Sicherheit und Effizienz sorgen.

Jahre Erfahrung

Wir liefern seit über 25 Jahren effektive Lösungen für den Materialtransport.

Länder

Unsere Maschinen werden von Kunden in der ganzen Welt eingesetzt.

Ausgelieferte Maschinen

Unsere Elektroschlepper werden tagtäglich eingesetzt, um sichere und effiziente Lastentransporte zu ermöglichen.

Kompakte, leistungsstarke Elektroschlepperlösungen

Unsere akkubetriebenen Elektroschlepper und Zughilfen sind nach dem gleichen Prinzip konstruiert – zuverlässige Leistung, egal ob Sie 500kg oder über 30.000kg bewegen.

Kompakt

Bis zu 6.000kg

.jpg?width=500&height=280&name=Compact-nav_280x340%20(1).jpg)

Sie benötigen Lösungen für die Materialhandhabung, die die Sicherheit und Effizienz verbessern? Mit unseren elektrischen Zughilfen können Sie Lasten ...

Performance

Bis zu 30.000kg

.jpg?width=500&height=280&name=Performance-nav_280x340%20(1).jpg)

Das Bewegen schwerer Lasten ist unser Metier. Unser Performance-Sortiment an Elektroschleppern ermöglicht es Ihnen, mit einer einzigen Maschine bis ...

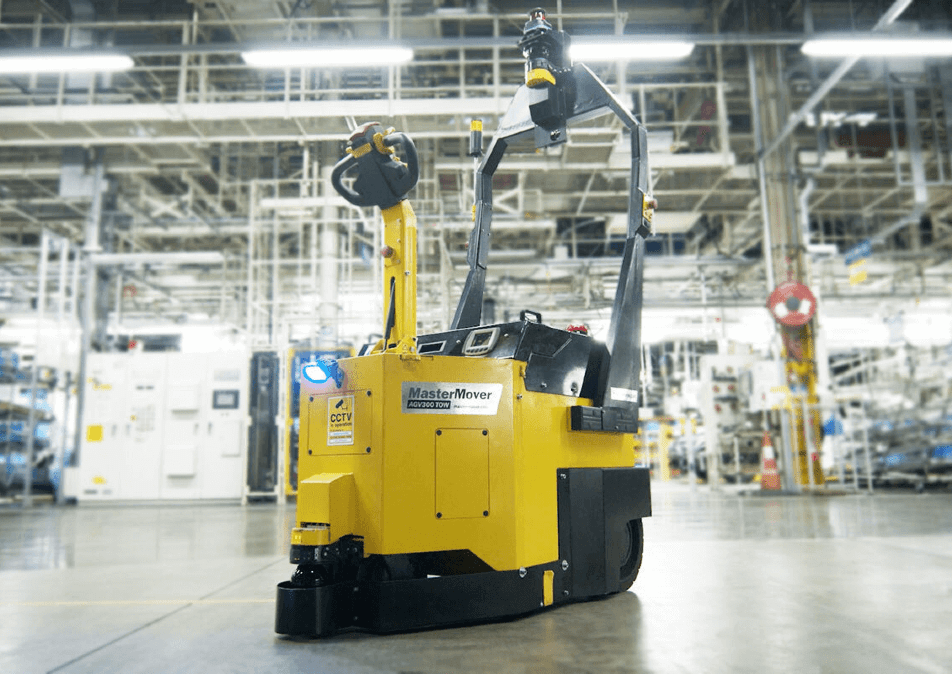

Fahrerlose Transport Systeme (FTS)

Bis zu 30.000kg

Nutzen Sie die Vorteile der vollautonomen Bewegung von Lasten bis zu 30.000kg. Erzielen Sie mehr Effizienz und verschlanken Sie Ihre Prozesse.

Elektroschlepper nach Baureihe

SmartMover

Bis zu 2.000kg

Die kompakten und leistungsstarken SmartMover sind der ideale Ersatz für die manuelle Handhabung – sie bieten mehr Sicherheit in Industrie, ...

MasterTow

Bis zu 20.000kg

Effiziente und leistungsstarke Elektroschlepper zum Bewegen von Lasten bis 20.000kg.

MasterTug

Bis zu 20.000kg

Mit der MasterTug-Reihe kann ein einzelner Mitgänger mühelos rollfähige Lasten bis 20.000kg schieben, ziehen und manövrieren.

MasterHandler

Bis zu 4.000kg

Nutzen auch Sie die sehr hohe Manövrierfähigkeit der MasterHandler auf engstem Raum, eigens entwickelt zum sicheren Bewegen von Lasten die ...

AllTerrain

Bis zu 5.000kg

Die AllTerrain-Reihe bietet hohe Leistung in anspruchsvollen Umgebungen zum sicheren Bewegen schwerer Lasten auf Schienen und Rollen.

Trailer Moving System

Bis zu 20.000kg

Das Trailer Moving System ist die ideale Lösung zum Bewegen unbeladener Auflieger bis 20.000kg in der Produktion und auf dem Hof.

PowerSteered

Bis zu 30.000kg

Ferngesteuerte Lösungen für maximale Übersicht beim Bewegen von Lasten bis 30.000kg und mehr mit unserer patentierten MultiLink-Lösung.

Edelstahl

Bis zu 15.000kg

Elektroschlepper in Edelstahlausführung aus hochwertigem 316er Edelstahl und mit Schutzart bis IP55 sind ideal für die Produktion von Lebensmitteln ...

Lösungen für die Industrie

Elektroschlepper verbessern die Sicherheit am Arbeitsplatz und steigern die betriebliche Effizienz in einer Reihe von Branchen. Ob beim Bewegen von Gitterboxen im Einzelhandel, von Verbundwerkstoffen in der Luft- und Raumfahrtindustrie oder sogar beim Bewegen von Windturbinenflügeln – Sie sind in sicheren Händen.

Luft- und Raumfahrt

Material in der Luft- und Raumfahrtindustrie sicherer bewegen mit Elektroschleppern.

Energie & Petrochemie

Höchste Leistung beim Manövrieren schwerer Lasten in der Energieindustrie.

Automotive & Land -und Baumaschinen

Schlanke Prozesse und höhere Flexibilität im Produktionsbereich mit Elektroschleppern.

Lebensmittel & Getränke

Elektroschlepper statt manueller Handhabung von Lebensmitteln für ein sichereres Arbeiten, maximale Effizienz und geringere Verletzungsgefahr.

Einzelhandel, Logistik & Lagerwesen

Der ideale Ersatz für eine manuelle Handhabung für höchste Effizienz und Sicherheit in Einzelhandel und Logistik.

Pharmazeutik & Life-Sciences

Sicheres Bewegen schwerer und wertvoller Lasten ersetzt manuelle Handhabung für eine maximale Effizienz in der Produktion.

Gebäude- & Abfallmanagement

Ersatz der manuellen Handhabung und höchste Sicherheit im Gebäude- und Abfallmanagement.

Produktion & Montage

Die Industrie vertraut in der Produktion auf Elektroschlepper für eine höhere Arbeitssicherheit und betriebliche Effizienz.

FTS - Lösungen

Vollständig autonomes Bewegen von Lasten

Ein Fahrerloses Transportsystem (FTS) sorgen für mehr Effizienz in der industriellen Fertigung. Mit branchenführender Navigations- und Sicherheitstechnologie machen FTS die Bedienung durch Menschen überflüssig und führen die Bewegung von Produkten, Ausrüstung und Materialien ausnahmslos pünktlich durch.

Ich kann das MasterMover FTS anderen Unternehmen, die ihre Fahrprozesse automatisieren möchten, nur empfehlen.

Kevin JonesLeitender Ingenieur Montagetechnik, Toyota Motor Corporation

Wir konnten die Elektroschlepper an vielen Standorten einführen und haben von den Benutzern nur positive Rückmeldungen erhalten.

Joel OddouxHSE Manager Sicarev

Sie sind qualitativ hochwertig, zuverlässig und einfach zu bedienen. Außerdem bieten sie eine fantastische Kontrolle und Bewegung in engen Bereichen – sie eignen sich also ideal für den Einsatz in der Biopharmabranche.

John O'ReillyStrikebox Engineering

Dank der Schlepper konnten wir die Art und Weise, wie wir unsere Einheiten produzieren, umstellen und die Werkstatt so effizienter und sicherer gestalten.

Steve GriffithsSelect Plant Hire

Die SmartMover-Elektroschlepper funktionieren wirklich gut für das, was wir brauchen, insbesondere beim Überwinden von Steigungen.

Jim FrielFriel Enterprises

Sind Sie bereit für einen sichereren Betrieb?

Möchten Sie die Sicherheit und Effizienz in Ihrem Betrieb verbessern? Kontaktieren Sie uns, um herauszufinden, wie Sie Ihre Prozesse mit einem Elektroschlepper oder einer elektrischen Ziehhilfe umgestalten können, um die Effizienz zu steigern und die Sicherheit am Arbeitsplatz zu maximieren.