Continue reading

Continue reading

Heavy-duty handling solutions for offshore and onshore

Petrochemical

Petrochemical plants handle heavy loads in some of the most challenging and extreme environments.

Hazardous environments and heavy loads mean that petrochemical plants and refineries need to rely on material handling equipment that delivers on safety – every time.

Large loads, tight spaces and challenging environments

Petrochemical plants and oilfields still often rely on cumbersome equipment such as overhead cranes and winches to move heavy loads. But for the movement of heavy production equipment on wheels, this can be cumbersome and inflexible.

Petrochemical plants need compact material handling solutions that deliver the controlled movement of loads in tight spaces to maximise safety – even in the toughest of environments.

Compact, robust electric tugs for petrochemical plants

With compact machine designs, ATEX protection and robust constructions, electric tugs are ideal solutions for meeting the challenges of the petrochemical industry.

Delivering the controlled movement of heavy loads in tight spaces and around corners, a single operator can safely move loads of 70,000kg and beyond.

Whether working on chequer plating, grating or rough, wet surfaces, electric tugs provide consistent performance and traction, guaranteeing the seamless movement of equipment.

Benefits for petrochemical plants

Used to deliver the safe, controlled movement of loads in the petrochemical and oil and gas industry, electric tugs maximise safety in hazardous environments.

-

Built to perform for you

When moving large, high-value loads in challenging environments, you need solutions that are built to perform.

With robust, industrial designs, electric tugs can safely move loads of 70,000kg and beyond.

-

Maximum manoeuvrability

Compact machines deliver unrivalled manoeuvrability, enabling the safe movement of loads in tight spaces and round corners.

-

Safe, controlled movement of wheeled loads

Purpose designed for moving wheeled loads, electric tugs securely connect to equipment, maximising control.

Our range of petrochemical moving electric tugs

MasterTug

Up to 20,000 kg

The MasterTug range allows a single pedestrian operator to easily push, pull and steer wheeled loads weighing up to 20,000kg.

MasterTow

Up to 20,000 kg

Drive safety and efficiency with our powerful electric tow tugs, designed to safely move loads of up to 20,000kg.

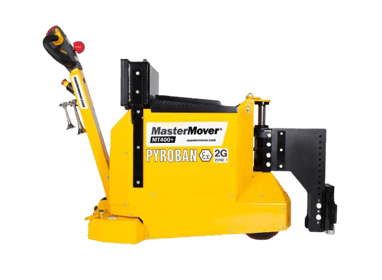

ATEX/IECEx

Up to 70,000 kg

Durable electric tug solutions for hazardous environments.

ATEX Range

Custom solutions for potentially explosive environments

All the safety and efficiency benefits of electric tugs but converted to work in the most challenging environments.

With machines available with Zone 1 & 2 protection in gaseous and 21 & 22 in dust environments – you can be assured that any solution is safe for use in your environment.

Trusted by global petrochemical plants and oilfields

Electric tugs are trusted by global petrochemical giants to deliver the safe, controlled movement of heavy loads in the most challenging environments.

MasterMover are easy to work with and all products performed as advertised. Moved our heavy products with ease!

Parker MacciantiMechanical Engineer

Your Questions, Answered - FAQs

Yes, all of our electric tugs can be converted to meet ATEX standards. Our electric tugs can be converted to operate in zones 1 and 2 (gaseous explosive environments) and zones 21 and 22 (powder or dust explosive environments) to meet ATEX and IECEx standards.

Working with best-in-class explosion-proofing providers, MasterMover ATEX electric tow tugs can safely work in hazardous environments, allowing you to maximise workplace safety and efficiency.

Yes, our electric tow tugs can work on common types of flooring, such as steel grating and chequer plates.

Our MasterTow range of industrial electric tow tugs is built with the durability needed to work on rough flooring like steel grating.

Yes, our electric tugs can be used offshore. All of our mild steel and stainless steel solutions can be converted to ATEX standards for use on oilfields.

Custom solutions with higher ingress protection (IP) ratings and marine-grade paint and coatings are available.

A range of coupling options are available across the range that maximise performance, security and safety.

Custom coupling solutions can also be designed for unique applications.

We're here to help

If you’re looking to improve safety, remove the risk of injury and unlock greater operational efficiency, we’re here to help. Speak to our team to discuss your application.

Interested in learning more? Read the latest articles

Continue reading

Continue reading